Resins are widely used in various industries due to their different properties and uses. Two commonly used resin types are epoxy resin and general purpose resin. Although both are classified as resins, they have different properties and different uses. Let’s explore the differences between epoxy resins and general-purpose resins, such as their chemical composition, properties, applications, and benefits. Understanding these differences is important in selecting the right resin for a specific application and obtaining the best results. Hope this helps.

We can compare and understand in multiple dimensions from the following aspects:

chemical composition:

Epoxy Resin: Epoxy resin is a thermosetting polymer composed of epoxy monomers. These monomers contain reactive epoxy groups and have a three-membered cyclic ether structure. Epoxy resins are typically produced by reacting bisphenol A (BPA) or similar compounds with epichlorohydrin. The resulting polymer has a linear or branched chain structure with multiple epoxy groups.

General Purpose Resins: General purpose resins refer to a broad category of resins that include many types, such as polyester resins, polyurethane resins, or vinyl ester resins. The chemical composition of general-purpose resins may vary depending on the specific type. For example, polyester resin is usually produced by the reaction of dibasic organic acids and polyols. Polyurethane resins are formed by the reaction of polyisocyanates and polyols, while vinyl ester resins are formed by the esterification of epoxy groups with unsaturated carboxylic acids.

Performance Characteristics:

Epoxy resin:

Chemical Resistance: Epoxy resins have excellent chemical resistance and are resistant to a wide range of chemicals, including acids, alkalis, solvents and oils. This property allows its use in corrosive environments.

Adhesion: Epoxies have strong adhesive properties, providing excellent bonding to a variety of substrates including metal, concrete, wood and composites. It forms lasting and lasting connections.

Mechanical strength: Epoxy resin has high mechanical strength, including tensile, compressive and flexural strength. This characteristic makes it suitable for applications requiring structural integrity and load-bearing capacity.

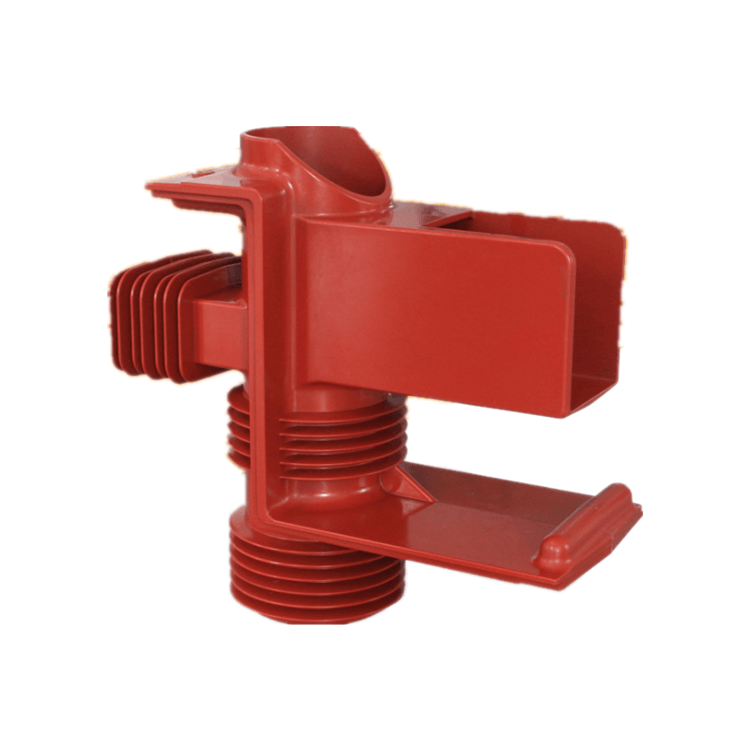

Electrical Insulation: Epoxy resin is an excellent electrical insulator with high dielectric strength and low dielectric loss. It has a wide range of uses in electrical and electronic applications.

Heat resistance: Epoxy resin has good heat resistance and can withstand high temperatures without significant deformation or degradation. It is typically used in applications exposed to high temperatures.

General resin:

Versatility: General-purpose resins offer a wide range of properties and can be customized to meet specific application requirements. They can be formulated to exhibit varying levels of chemical resistance, mechanical strength, flexibility and other desired properties.

Cost-Effectiveness: Generally speaking, general-purpose resins are more cost-effective than epoxies, making them suitable for applications where cost is a primary consideration.

Application-specific properties: Different types of general-purpose resins have unique properties. For example, polyester resins are known for their excellent corrosion resistance, while polyurethane resins offer excellent flexibility and impact resistance. Vinyl ester resin combines the chemical resistance of epoxy resin with the flexibility of polyester resin.

Epoxy Resin and Resin Advantages:

Epoxy resin:

- Excellent chemical resistance and adhesive performance

- High mechanical strength & durability

- Superior electrical insulation performance

- Good thermal resistance

- Broad application range

General resin:

- Application-specific customizable properties

- Cost-effective compared to epoxy

- Multiple types to choose from to meet different needs

- Unique advantages based on specific resin types

To summarize, epoxy resins and general-purpose resins are two different types of resins with different chemical compositions, properties, and applications. Epoxy resins are known for their excellent chemical resistance, adhesion, mechanical strength, electrical insulation and heat resistance. It can be used in adhesives, coatings, electrical components and composite materials. General-purpose resins, on the other hand, offer versatility, cost-effectiveness, and application-specific properties. They are widely used in industries such as fiberglass products, casting, molding, coatings, adhesives and sealants. By understanding the differences between epoxy and general-purpose resins, professionals can make an informed decision in selecting the resin best suited for their specific application, taking into account factors such as chemical resistance, mechanical properties, cost and desired performance characteristics .