In the world of electrical engineering and materials science, insulators play a critical role in the safe and efficient transmission of electrical energy. These materials prevent the flow of electric current, helping to isolate and protect conductors and equipment from unwanted electrical interference. The choice of the best type of insulator depends on various factors, including the specific application, environmental conditions, and the desired electrical properties. This comprehensive article aims to explore the various types of insulators, their properties, and the criteria for selecting the best insulator for a given application.

Understanding Insulators

Insulators, also known as dielectrics, are materials with high electrical resistance, which means they do not conduct electric current effectively. In contrast to conductors, which facilitate the flow of electrons, insulators inhibit this flow, making them essential components in electrical systems. The ability of insulators to resist the passage of electric current is quantified by their electrical resistance, which is typically measured in ohms. This resistance is inversely proportional to the insulator’s conductivity, with higher resistance indicating better insulating properties.

Types of Insulators

There are several types of insulators used in various applications, each with its unique properties and characteristics. The selection of the best insulator depends on the specific requirements and conditions of the application. Here are some common types of insulators:

- Ceramic Insulators: Ceramic materials, such as porcelain and alumina, are widely used in electrical and high-voltage applications. They offer excellent mechanical strength and high resistance to electrical stress, making them suitable for insulating power lines and electrical equipment.

- Polymer Insulators: Polymer insulators are lightweight and resistant to corrosion, making them suitable for outdoor applications. They are often used in power distribution systems and are favored for their durability in harsh weather conditions.

- Glass Insulators: Glass insulators provide high resistance to electrical conductivity and are used in various applications, including telecommunications and electrical distribution.

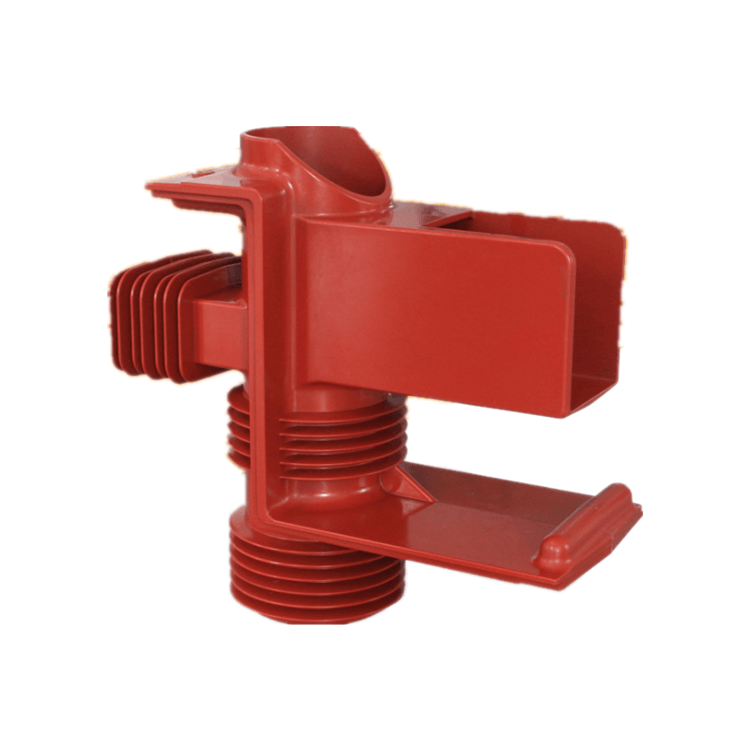

- Composite Insulators: Composite insulators combine different materials, such as fiberglass rods and silicone rubber, to create insulators with superior electrical and mechanical properties. They are commonly used in high-voltage transmission lines and substations.

- Air Insulators: Air itself can serve as an insulator when the distance between conductors is sufficient to prevent electrical breakdown. Air-insulated systems are cost-effective and commonly used in overhead power transmission lines.

Factors for Selecting the Best Insulator

Choosing the best insulator for a specific application involves evaluating several critical factors to ensure optimal performance and safety. These factors include:

- Electrical Resistance: The insulator’s electrical resistance should be suitable for the intended voltage and current levels. Higher voltage applications require insulators with greater resistance.

- Mechanical Strength: Insulators must withstand mechanical stress, including wind, ice, and vibration. The insulator’s mechanical strength is crucial, especially in overhead power lines and substations.

- Environmental Conditions: Consideration must be given to the environmental conditions in which the insulator will be used. Factors like temperature extremes, humidity, and pollution levels can impact insulator performance.

- Corrosion Resistance: In outdoor applications, insulators should be resistant to corrosion. This is particularly important in coastal or industrial areas with high levels of pollution.

- Frequency and Frequency Response: Some applications, such as high-frequency electronics, may require insulators with specific frequency response characteristics.

- Cost and Availability: The cost-effectiveness of the insulator and its availability in the market are essential factors, especially in large-scale projects.

- Maintenance Requirements: The ease of maintenance is an important consideration. Some insulators may require regular cleaning and inspection, while others can be considered maintenance-free.

- Safety and Insulation Coordination: Ensuring that the insulator’s properties align with the overall insulation system is crucial to prevent electrical breakdown.

Each of these factors plays a critical role in determining the best type of insulator for a particular application. Engineers and researchers carefully assess these variables to select the most appropriate insulator that meets the project’s requirements.

Applications of Different Insulators

The choice of insulator type also depends on the specific application and the electrical equipment involved. Let’s delve into some common applications and the types of insulators suitable for each:

- High-Voltage Transmission Lines: High-voltage power transmission lines, which carry electricity over long distances, often use ceramic and composite insulators due to their excellent electrical and mechanical properties. These insulators provide the necessary insulation and support.

- Telecommunications: Glass insulators are commonly used in telecommunications applications to isolate electrical conductors and support communication infrastructure.

- Switchgear and Substations: Polymer insulators are favored in switchgear and substations due to their lightweight design and resistance to pollution and contamination.

- Railway Electrification: Composite insulators are used for railway electrification systems to provide electrical insulation and mechanical support for overhead lines.

- Household Appliances: In everyday appliances, such as refrigerators and washing machines, insulators made of materials like plastic are used to provide electrical safety.

- Electronics: Insulators in electronic devices are designed with specific dielectric materials to meet the frequency response and electrical properties required for the application.

Conclusion

The choice of the best type of insulator is a complex decision that involves evaluating various factors, including electrical resistance, mechanical strength, environmental conditions, and cost. The selection of insulators is critical for the safe and efficient operation of electrical systems and equipment. Different types of insulators, including ceramic, polymer, glass, composite, and air insulators, each have their unique properties and advantages, making them suitable for specific applications.

As technology continues to advance, research and development in the field of insulating materials are ongoing. Engineers and materials scientists work to create insulators with improved performance, reduced environmental impact, and increased durability. The future of insulators holds the promise of even more efficient and sustainable electrical systems.

In conclusion, the best type of insulator depends on the specific requirements of the application and a careful consideration of factors like electrical resistance, mechanical strength, environmental conditions, and cost. The appropriate choice of insulator is essential to ensure the safe and reliable operation of electrical systems across various industries.