In power systems, busbars are important components used to distribute power. Busbars are conductive strips or strips that carry and distribute electrical current within an electrical system. At the same time, in order to ensure safe and reliable operation, the busbar must be properly insulated from its surrounding environment. This is where busbar insulators come into play. Busbar insulators are components specifically designed to provide electrical insulation and mechanical support for busbars.

Definition and function:

Busbar insulators, also known as busbar support insulators, are devices used for electrical insulation and mechanical support of busbars in power systems. Its main function is to prevent electrical contact between the busbar and the supporting structure to ensure safe and reliable operation of the power system. Busbar insulators are designed to withstand the electrical and mechanical stresses associated with busbar operation, such as voltage, current, thermal expansion and vibration.

Types of busbar insulators:

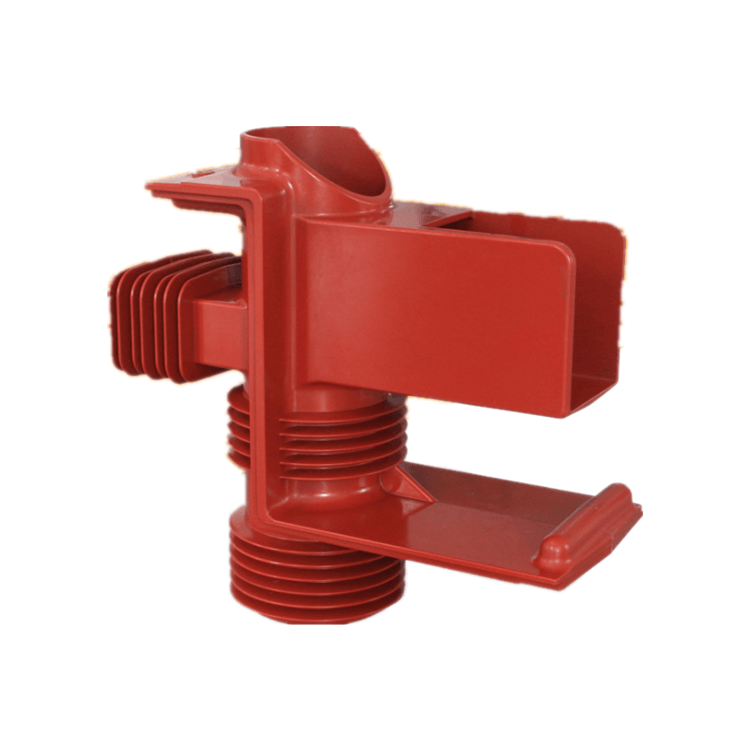

1. Solid Busbar Insulators: Solid busbar insulators are made from a single piece of insulating material such as porcelain, glass, or polymer. They come in a variety of shapes, including cylindrical, rectangular and flange designs. Solid insulators offer high electrical insulation and mechanical strength, making them suitable for applications with high voltage and current levels.

2. Composite bus insulators: Composite bus insulators are constructed from a combination of different materials, such as fiberglass reinforced plastic (FRP) rods and silicone rubber casings. These insulators provide excellent electrical insulation, mechanical strength and resistance to environmental factors such as UV radiation, chemicals and moisture. Composite bus insulators are lightweight, durable and suitable for a variety of applications.

3. Insulated busbar system: An insulated busbar system consists of busbars completely enclosed within an insulating enclosure or pipe. The housing is made of insulating material such as epoxy, polyester or silicone rubber. Insulated busbar systems provide enhanced electrical insulation, prevent accidental contact and are easy to install.

Busbar insulator material:

1. Porcelain: Porcelain has excellent electrical and mechanical properties and is the traditional material for busbar insulators. It has high resistance, good thermal stability and resistance to environmental factors. Porcelain insulators are known for their durability and long lifespan.

2. Glass: Glass insulators have properties similar to porcelain insulators, including high electrical resistance and mechanical strength. They are often used in applications that require transparency or specific optical properties.

3. Polymers: Polymer-based insulators, such as silicone rubber, epoxy or polyester, are increasingly popular in modern busbar insulation systems. These materials are lightweight, flexible, easy to install, and resistant to UV radiation, chemicals, and moisture. Polymer insulators can be molded into complex shapes, allowing for custom designs.

4. Composite materials: Composite bus insulators combine different materials, such as fiberglass rods and silicone rubber casings. The combination of materials provides increased mechanical strength, electrical insulation, and resistance to environmental factors. Composite materials provide a balance between strength and weight, making them suitable for a variety of applications.

Application:

Busbar insulators are used in a variety of power system applications including:

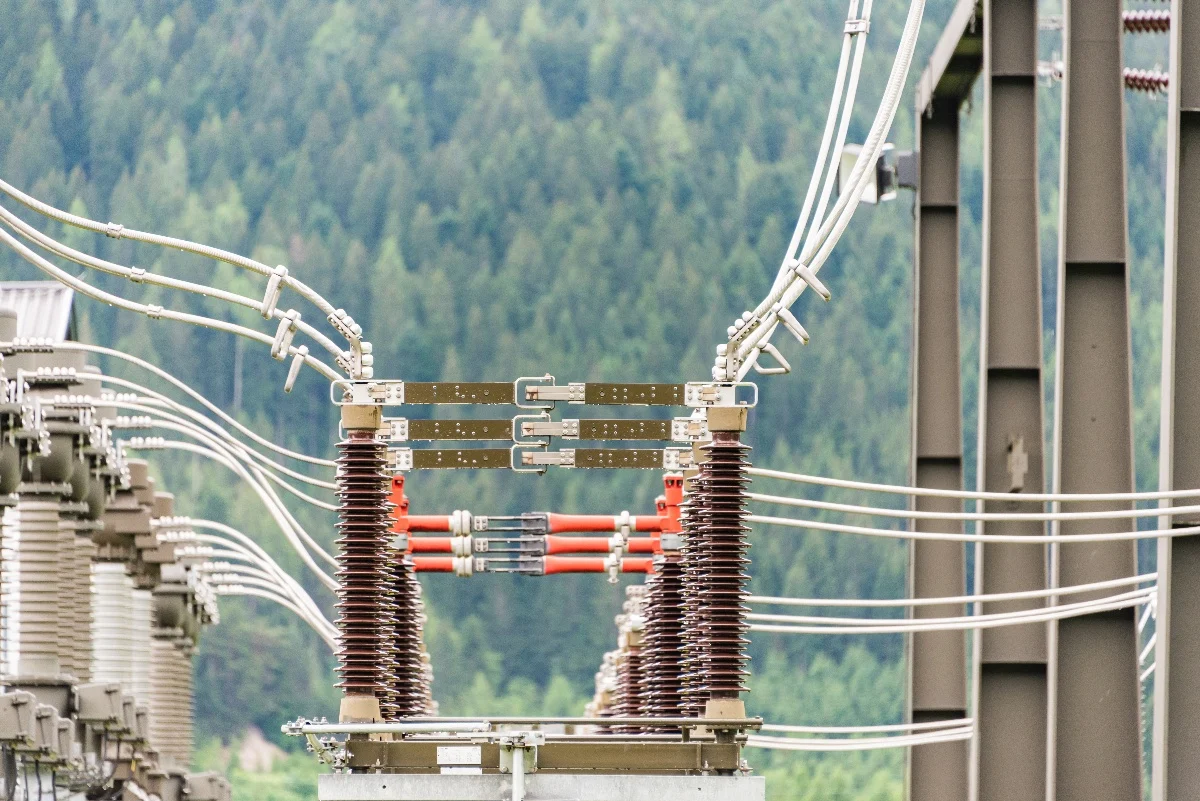

1. Substation: Busbar insulators are used in substations to support and insulate the busbars that distribute power from the transformers to different parts of the grid.

2. Switchgear and Circuit Breakers: Busbar insulators are used in switchgear and circuit breaker systems to provide insulation and support for the busbars that connect and distribute electrical current within these systems.

3. Power Generation: Busbar insulators are used in power generation facilities, such as thermal power plants, hydroelectric plants and wind farms, to insulate and support busbars within generator and transformer systems.

4. Industrial applications: Busbar insulators can be used in various industrial environments requiring power distribution. Examples include manufacturing plants, data centers, and commercial buildings.

5. Railways and Transportation: Busbar insulators are used in railway systems, trams, and electric vehicle charging stations to insulate and support the busbars that supply power to trains or charging infrastructure.

The Meaning:

Busbar insulators play a vital role in ensuring the safe and reliable operation of power systems. Their meaning can be summarized as follows:

1. Electrical Safety: Busbar insulators prevent leakage, short circuits, and electrical faults by providing electrical insulation. They help protect people, equipment and the surrounding environment from electrical hazards.

2. System Reliability: Busbar insulators contribute to the overall reliability of the power system by maintaining proper electrical isolation between the busbars and the supporting structure. This minimizes the risk of system failure, downtime and equipment damage.

3. Mechanical stability: Busbar insulators provide mechanical support, stability, and alignment to the busbar, ensuring its structural integrity under normal and abnormal operating conditions. They are able to withstand mechanical stress and vibration, maintaining the mechanical stability of the busbar system.

4. Environmental resistance: Busbar insulators are designed to withstand a variety of environmental factors, including temperature changes, humidity, UV radiation, and chemical exposure. Their resistance to these factors ensures long-term performance and reliability in diverse operating environments.

5. Easy to install: Busbar insulators are designed to be easy to install and securely fastened, promoting an efficient and cost-effective installation process. Their design allows flexible mounting options to accommodate different system configurations.

Busbar insulators are key components in power systems, providing electrical insulation and mechanical support for busbars. With their different types, materials and design considerations, they ensure safe and reliable operation of power systems in a variety of applications. It contribute to electrical safety, system reliability and overall performance by preventing electrical contact, providing mechanical stability and withstanding environmental factors. As technology advances, the development of innovative insulation materials and designs continues to enhance the function and effectiveness of busbar insulators in modern electrical systems.