Introduction: Unveiling the Composition of Standoff Busbars in Commercial Applications

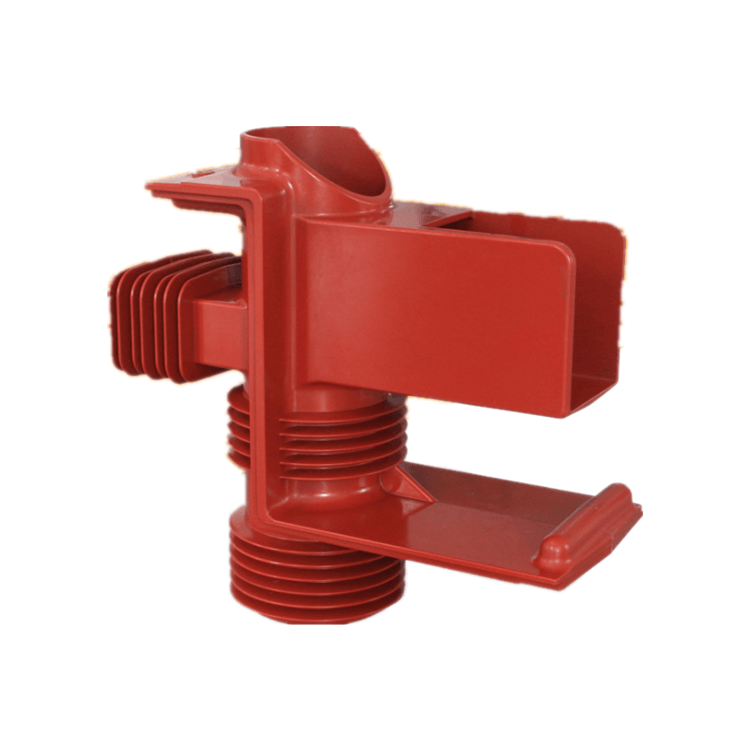

CPI Standard Busbars are specialized insulated ground bus mounting plates designed for commercial applications, featuring Hard-Drawn Electrolytic Tough Pitch 110 Alloy solid copper bonding bars. These busbars come in varying configurations, with thicknesses of 1/4″ and stand-off distances of 2.75″. The 10″ Busbar accommodates 1/4″ single bolt lugs, while the 12″ and 20″ configurations provide connections for nine or 17 lugs, accepting sizes with 3/4″, 1″, or 1-3/4″ centers. Compatibility extends to lugs with 3/8″ bolts. Each busbar assembly includes essential components like insulators, stand-off brackets, stainless steel bolts, lock washers, and flat washers, all shipped individually and preassembled for convenience. This comprehensive summary outlines the material composition, dimensions, configurations, lug compatibility, assembly components, and shipping details of Standoff Busbars, providing a holistic understanding of their design and functionality in commercial settings.

Providing an overview, this section introduces CPI Standard Busbars, emphasizing their purpose as insulated ground bus mounting plates designed specifically for commercial applications. The focus then shifts to the key material—hard-drawn Electrolytic Tough Pitch 110 Alloy solid copper bonding bars—and their specifications.

The specific dimensions of the busbars, with a thickness of 1/4″ and a stand-off distance of 2.75″, are critical design considerations. These dimensions are carefully chosen to strike a balance between structural integrity and space efficiency, catering to the practical requirements of various installations. The 10″ Busbar configuration, designed to accept 1/4″ single bolt lugs, provides a streamlined solution for specific applications, offering a practical and efficient connection point.

The versatility of the 12″ and 20″ Busbar configurations is a notable feature, allowing for the connection of nine or 17 lugs, respectively. This adaptability is particularly valuable in commercial settings where varying loads and equipment configurations may be present. The acceptance of lugs with different center sizes, ranging from 3/4″ to 1-3/4″, adds an extra layer of flexibility, ensuring compatibility with a wide range of electrical components.

Examining lug compatibility further, the ability to accommodate lugs with 3/8″ bolts expands the range of options for users. This consideration takes into account the diverse specifications of lugs available in the market, providing users with the freedom to choose components that best fit their specific requirements. The flexibility in lug compatibility contributes to the universal applicability of Standoff Busbars in commercial electrical systems.

An in-depth look at the complete assembly of Standoff Busbars reveals a thoughtful design that encompasses all necessary components. The inclusion of insulators, stand-off brackets, stainless steel bolts, lock washers, and flat washers ensures a comprehensive solution for users. Each component plays a crucial role in the overall functionality and safety of the busbar assembly. The use of stainless steel bolts, known for their corrosion resistance, adds a layer of durability, particularly relevant in environments where exposure to moisture or harsh conditions is a concern.

The shipping and preassembly approach adopted for Standoff Busbars further enhances their user-friendliness. By shipping each busbar assembly individually and preassembled, the manufacturer streamlines the installation process for end-users. This approach not only saves time but also reduces the likelihood of errors during installation, contributing to the overall efficiency and reliability of the electrical system.

Material Composition: Exploring the Hard-Drawn Electrolytic Tough Pitch 110 Alloy

Delving into the heart of the matter, this paragraph provides a detailed exploration of the material composition of Standoff Busbars. The spotlight is on the Hard-Drawn Electrolytic Tough Pitch 110 Alloy, unraveling its properties and why it is chosen for the construction of these critical components.

Thickness and Standoff: Dimensions of CPI Standard Busbars

Highlighting the physical attributes of CPI Standard Busbars, this section discusses the specific dimensions of the Hard-Drawn Electrolytic Tough Pitch 110 Alloy solid copper bonding bars. It details the thickness of 1/4″ (6.4 mm) and the stand-off distance of 2.75″ (70 mm) from the backboard or wall, shedding light on the significance of these measurements.

Single Bolt Lugs: The 10″ Busbar Configuration

Focusing on the 10″ (254 mm) Busbar configuration, this paragraph delves into its compatibility with 1/4″ (6.4 mm) single bolt lugs. It explores the practical implications of this design choice and how it enhances the functionality of the busbar in commercial settings.

Versatility in Connection: The 12″ and 20″ Busbar Configurations

Expanding on the product range, this section introduces the 12″ (304.8 mm) and 20″ (508 mm) Busbar configurations. It details their capacity to provide connections for nine or 17 lugs respectively, accommodating various lug sizes with different center distances. The versatility of these configurations is a key aspect of their design.

Lug Compatibility: A Closer Look at Size and Bolt Specifications

Examining the intricate details of lug compatibility, this paragraph explores the options available for users. It details the accepted lug sizes of 3/4″, 1″, or 1-3/4″ (19 mm, 25.4 mm, or 44.5 mm) centers and emphasizes the flexibility provided by the Standoff Busbars, accommodating lugs with 3/8” (9.5 mm) bolts.

Comprehensive Assembly: Components of a Standoff Busbar Assembly

Offering an insight into the complete assembly, this section breaks down the components of a standoff busbar. It outlines the key elements, including the busbar itself, insulators, stand-off brackets, stainless steel bolts, lock washers, and flat washers. This comprehensive view aids in understanding the holistic structure of the busbar assembly.

Shipping and Preassembly: Streamlining the Standoff Busbar Process

Concluding the discussion, this paragraph sheds light on the logistics of Standoff Busbars. It details that all busbars are shipped individually and preassembled, highlighting the efficiency in delivery and installation processes. This ensures that users receive a ready-to-install product, streamlining the integration of Standoff Busbars into their commercial applications.

Related Products