Insulation is a critical component of many systems, structures, and equipment that are designed to manage and control temperature and energy. It plays a vital role in conserving energy, reducing heat loss or gain, and ensuring the safety and efficiency of various applications. Insulation materials are categorized into four distinct classes, each with its unique properties and applications. In this comprehensive article, we will explore these four classes of insulation, providing detailed insights into their characteristics, uses, and advantages. This knowledge will help you make informed decisions when choosing the most suitable insulation for your specific needs.

- Thermal Insulation

Thermal insulation is perhaps the most common type of insulation, as it is widely used in buildings, industrial equipment, and various appliances. Its primary purpose is to regulate heat flow, preventing heat from escaping during cold weather or entering during hot weather. The four primary types of thermal insulation materials include:

1.1 Fibrous Insulation

Fibrous insulation materials are among the most commonly used thermal insulators. They are made of fibrous materials like fiberglass, mineral wool, and cellulose. These materials are excellent at trapping air, which makes them effective insulators. They are commonly used in wall and ceiling insulation, as well as in HVAC (Heating, Ventilation, and Air Conditioning) systems.

1.2 Foam Insulation

Foam insulation materials, such as expanded polystyrene (EPS), extruded polystyrene (XPS), and polyurethane, are lightweight and have high insulating properties. They are used in various applications, including roofing, walls, and flooring, offering excellent thermal resistance. Foam insulation is known for its versatility and ability to fit into tight spaces.

1.3 Reflective Insulation

Reflective insulation materials consist of layers of aluminum or other reflective materials. They are designed to reflect radiant heat, making them particularly effective in attics, roofs, and walls. Reflective insulation is an ideal choice for applications where reducing radiant heat is the primary concern.

1.4 Loose-Fill Insulation

Loose-fill insulation materials are typically granular or fibrous and are blown or poured into cavities or open spaces. Common loose-fill insulation materials include cellulose, fiberglass, and mineral wool. They are used to fill irregular or hard-to-reach spaces, providing effective thermal insulation.

- Electrical Insulation

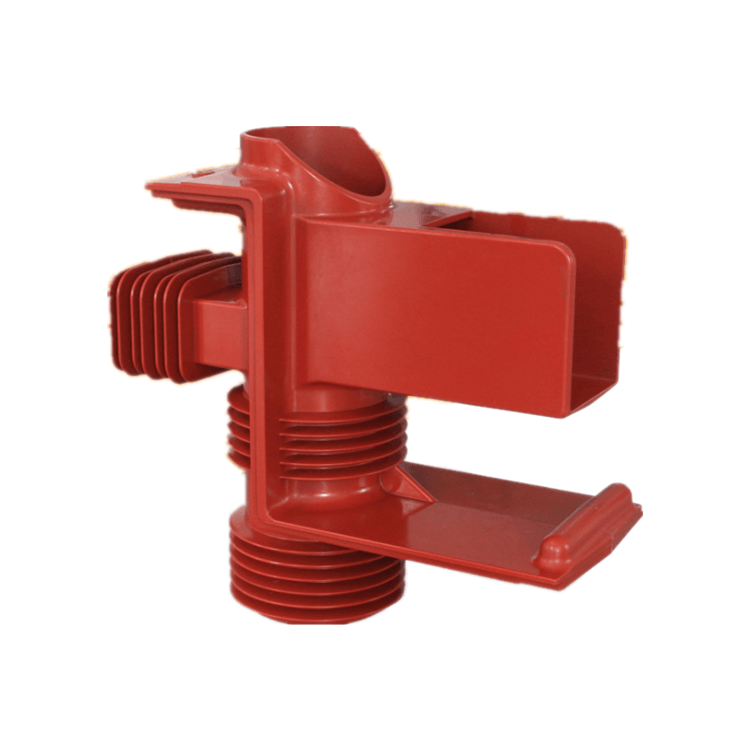

Electrical insulation is essential for preventing electrical currents from escaping or conducting inappropriately. This class of insulation is crucial in electrical systems and devices, ensuring safety and preventing electrical malfunctions. The four primary types of electrical insulation materials include:

2.1 Insulating Tapes

Insulating tapes are typically made of materials like vinyl, rubber, or mica. They are used to wrap electrical conductors, providing a protective barrier to prevent electrical leakage or short-circuits. Insulating tapes come in various sizes and are an integral part of electrical maintenance and repair.

2.2 Insulating Sheets and Boards

Insulating sheets and boards are rigid materials that are used to separate electrical components or to create barriers in electrical enclosures. Common materials used for insulating sheets and boards include fiberglass, epoxy, and phenolic resins. These materials offer high dielectric strength and thermal resistance.

2.3 Coatings and Varnishes

Coatings and varnishes are applied to the surface of electrical equipment and conductors to provide a protective layer. They are typically made of epoxy or polyurethane and offer excellent electrical insulation properties. These coatings are widely used in electrical motors and transformers.

2.4 Insulating Liquids

Insulating liquids, such as mineral oil, silicone oil, and transformer oil, are used in high-voltage electrical equipment. They serve as coolants and electrical insulators, preventing arcing and short-circuits. Insulating liquids are vital in large power transformers and capacitors.

- Acoustic Insulation

Acoustic insulation, also known as sound insulation or soundproofing, is essential for reducing the transmission of sound between spaces. It is widely used in buildings, industrial facilities, and transportation systems to create quieter and more comfortable environments. The four primary types of acoustic insulation materials include:

3.1 Fibrous Acoustic Insulation

Fibrous acoustic insulation materials, similar to their thermal insulation counterparts, are used to absorb and dampen sound. They are often used in walls, ceilings, and floors to reduce noise transmission. Common materials include mineral wool, fiberglass, and recycled cotton.

3.2 Acoustic Panels

Acoustic panels are rigid materials or boards designed to reflect, absorb, or diffuse sound. They are commonly used in auditoriums, recording studios, and commercial spaces to improve acoustics. These panels come in various shapes, sizes, and materials, allowing for custom sound control solutions.

3.3 Mass-Loaded Vinyl

Mass-loaded vinyl is a heavy, flexible material that is added to walls, ceilings, or floors to block sound transmission. It is particularly effective in reducing airborne and impact noise. Mass-loaded vinyl is a versatile soundproofing solution for both residential and commercial applications.

3.4 Acoustic Foams

Acoustic foams, often seen in wedge or pyramid shapes, are designed to absorb sound reflections and reduce reverberation. They are commonly used in home theaters, recording studios, and noisy machinery enclosures to improve sound quality. Acoustic foams come in a variety of densities and thicknesses.

- Thermal Insulation

Cryogenic insulation is a specialized type of insulation designed to withstand extremely low temperatures, typically below -150°C (-238°F). It is crucial in applications involving the storage and transportation of cryogenic fluids like liquefied natural gas (LNG) and liquid nitrogen. The four primary types of cryogenic insulation materials include:

4.1 Perlite Insulation

Perlite insulation is a lightweight, low-density material made from volcanic glass. It is commonly used in cryogenic storage tanks and equipment due to its exceptional thermal insulation properties. Perlite is an effective insulator in applications where space constraints are a concern.

4.2 Polyurethane Foam

Polyurethane foam insulation is known for its high thermal resistance and is often used in cryogenic pipelines and equipment. It provides excellent insulation in a compact form, making it suitable for applications where space is limited.

4.3 Vacuum Insulation Panels

Vacuum insulation panels (VIPs) consist of a core material, such as fumed silica or fiberglass, encased in a vacuum-sealed barrier. VIPs are extremely efficient insulators, offering very low thermal conductivity. They are used in applications where the highest level of insulation is required in a minimal space.

4.4 Aerogel Insulation

Aerogel insulation, often referred to as “frozen smoke,” is a highly porous material with an incredibly low thermal conductivity. It is used in specialized cryogenic applications, such as space exploration and scientific research. Aerogels provide unparalleled insulation performance in extreme cold environments.

Conclusion

In summary, the four classes of insulation – thermal, electrical, acoustic, and cryogenic – serve diverse purposes in various industries and applications. Each class encompasses a range of materials with unique properties and advantages tailored to their specific functions. Understanding the differences between these classes of insulation is essential for selecting the right materials to meet the requirements of a particular project. Whether you are insulating a building, ensuring electrical safety, soundproofing a room, or managing cryogenic temperatures, choosing the appropriate insulation class and material is crucial for success. By gaining a comprehensive understanding