-

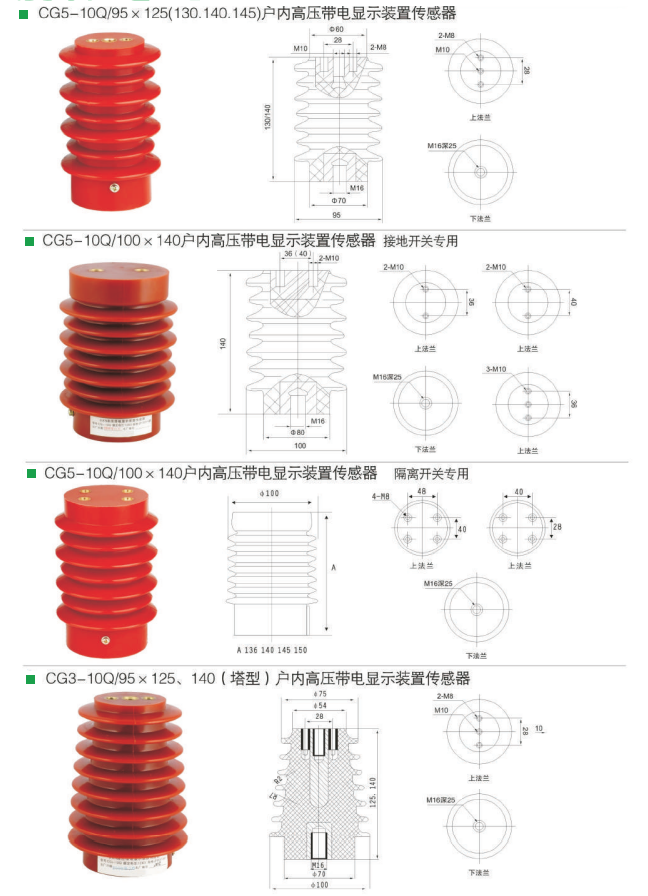

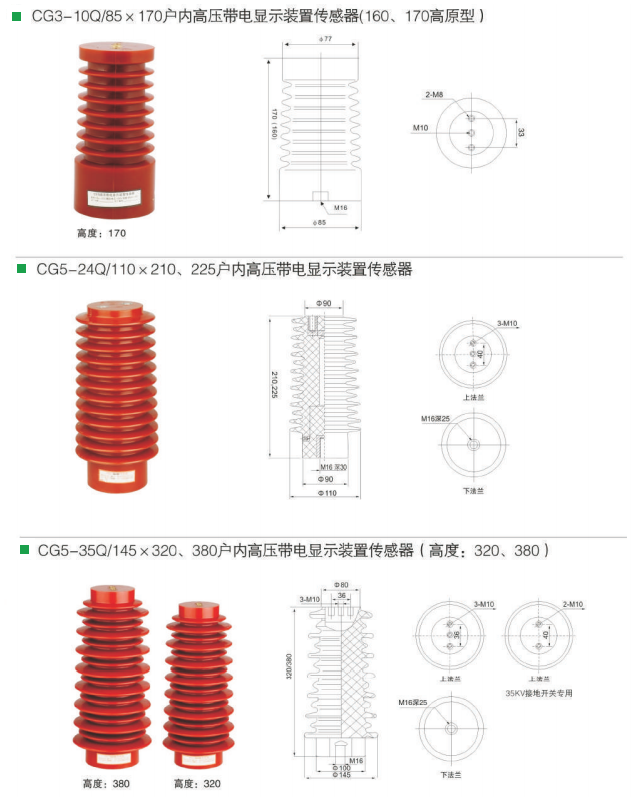

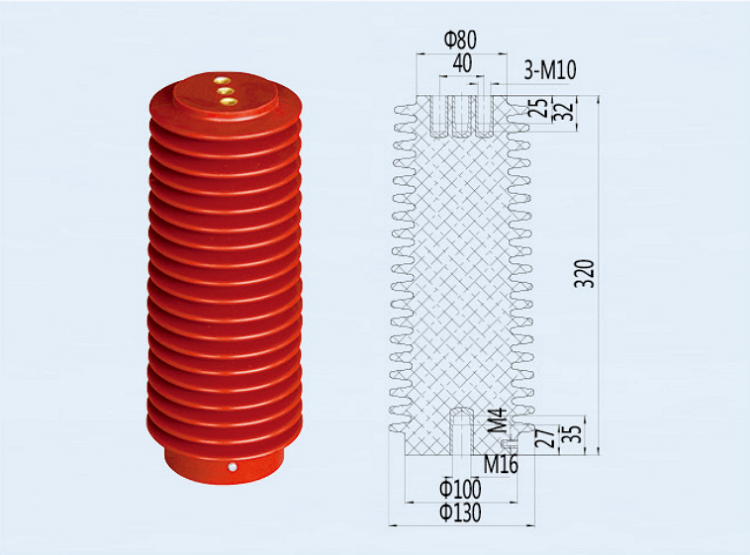

35KV Epoxy Resin Busbar Support Insulator For Distribution Cabinet

-

- Production Process and Manufacturing Techniques: The insulator undergoes a meticulous production process, beginning with the selection of high-quality epoxy resin materials. The manufacturing techniques involve precision molding and casting, ensuring the final product meets stringent quality standards. The process includes curing and post-treatment to enhance durability and electrical performance.

- Materials: The primary material utilized in the construction of this insulator is epoxy resin—a versatile and durable thermosetting polymer known for its excellent electrical insulating properties. Epoxy resin ensures high dielectric strength, mechanical robustness, and resistance to environmental factors such as moisture and contaminants.

- Applications: The 35KV Epoxy Resin Busbar Support Insulator is specifically designed for deployment in distribution cabinets, where it provides reliable support and insulation for high-voltage busbars. Its applications extend to various sectors, including power distribution stations, industrial facilities, and infrastructure projects requiring a dependable solution for electrical insulation.

- Distinctive Features: a. High Dielectric Strength: The insulator boasts a high dielectric strength, safeguarding against electrical breakdown and ensuring the integrity of the distribution system. b. Corrosion Resistance: The epoxy resin material confers corrosion resistance, making the insulator suitable for diverse environmental conditions. c. Mechanical Robustness: Rigorous manufacturing processes result in a mechanically robust product capable of withstanding mechanical stresses and vibrations. d. Ease of Installation: Designed for easy installation, the insulator contributes to the overall efficiency of the distribution cabinet assembly process.

- Electrical Characteristics: a. Voltage Rating: Rated for 35KV, the insulator effectively isolates and supports high-voltage busbars in distribution cabinets. b. Tracking Resistance: Exhibits excellent tracking resistance, preventing the formation of conductive paths on the insulator surface. c. Arc Resistance: With a high arc resistance, the insulator enhances the safety and reliability of the distribution system. d. Thermal Stability: Maintains stable electrical performance across a range of temperatures, ensuring reliability in diverse operational environments.

-

- Voltage:

35kv Height: 320mm Diameter: 130mm Screw: 3-M10 Material: Epoxy resin MOQ: 50pcs Certificate: CE, RoHS, REACH

High voltage sensor insulator description

The high-voltage sensor insulator serves a crucial role in monitoring and managing high-voltage charged circuits. By utilizing a capacitor core rod, it extracts a specific voltage from the circuit to power both the display and blocking functions. This enables the sensor to reflect the charged state of the device setting, allowing for the forced locking and switching of the network door. Importantly, the voltage indication and forced locking operations are coordinated by the same high-voltage signal, enhancing the overall efficiency of the system.

This epoxy resin cast pillar-type insulator is versatile, finding applications as an isolating switch, grounding switch, and other post insulators. Its design ensures a robust performance, characterized by high strength, strong arc resistance, and minimal partial discharge. The insulator’s independence between the display and locking circuits ensures that, even in the event of simultaneous failures in both circuits, the electromagnetic lock remains in a secure, locked state as long as the high-voltage circuit is charged. This inherent redundancy contributes to the product’s exceptional reliability and safety, making it an ideal choice for applications where consistent and fail-safe high-voltage management is paramount.

Application

The insulation sensor finds versatile applicability across a spectrum of industries, making it a valuable asset for various sectors. Primarily designed to enhance safety and efficiency, this sensor is well-suited for deployment in power, energy, industry, and infrastructure applications.

In the power sector, the insulation sensor plays a pivotal role in monitoring and managing high-voltage circuits, contributing to the reliable operation of power distribution systems. Its capacity to provide accurate voltage indication and support forced locking ensures the secure functioning of critical components within the power infrastructure.

Within the energy industry, the insulation sensor proves beneficial for safeguarding electrical equipment and maintaining the integrity of energy transmission networks. Its robust design and high-reliability features make it an essential tool for ensuring an uninterrupted energy supply.

In industrial settings, the insulation sensor contributes to the overall safety and efficiency of equipment operation. Its application as an isolating switch or grounding switch aids in preventing electrical malfunctions and minimizing the risk of downtime in industrial processes.

The sensor’s role extends to infrastructure projects, where its capabilities are harnessed for maintaining the electrical stability of key installations. Whether used in transportation systems, telecommunications networks, or other critical infrastructure, the insulation sensor provides a reliable means of monitoring and controlling high-voltage conditions.

Our service

| Delivery | By express/By sea/By air/By land transportation |

| Supply | 5000pcs/week |

| Sample | The seller provides 2 samples for free, and the buyer pays the freight |

| Packing | By carton |

More Related