Introduction: Navigating the Significance of Epoxy Resin Support Insulators

Epoxy Resin Support Insulators stand as crucial components in ensuring the safety and efficiency of distribution equipment, playing a pivotal role in supporting power infrastructure. The historical evolution from ceramic to epoxy resin insulators marks a significant shift, with Japan’s Lichang Industrial Co., Ltd. leading the way since 1974 through the pressure solidification method.

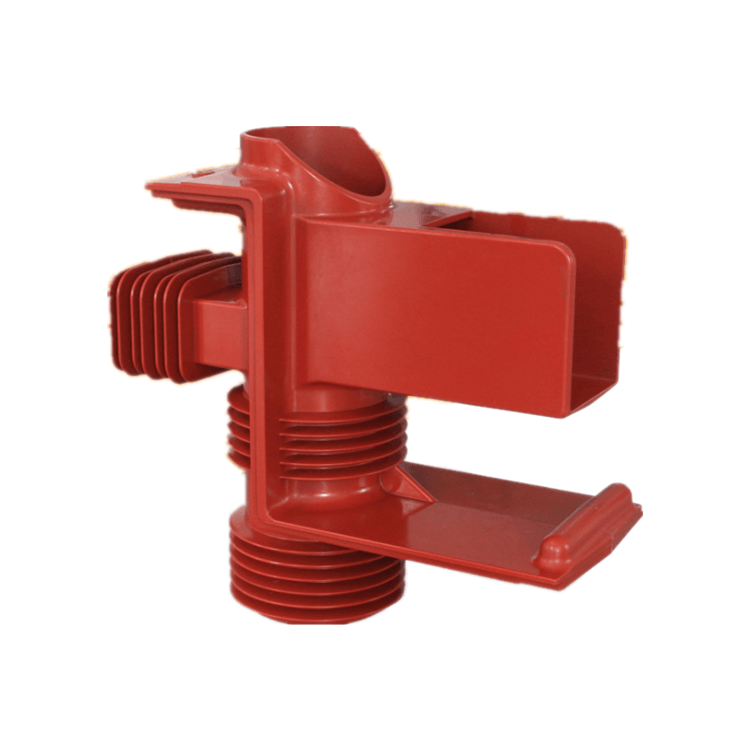

The manufacturing mastery involved in the production of epoxy resin support insulators, particularly the pressure solidification method, underscores the commitment to quality consistency. Advantages of epoxy resin, including its ability to allow deeper twists in the insulator’s curved surface, redefine insulator design by making them more compact and lightweight compared to traditional ceramic counterparts.

Gaoyi United emerges as a professional pioneer in the field, contributing to the advancement of epoxy resin insulation technology. The practical applications of epoxy resin support insulators span distribution cabinets, circuit breakers, and isolation switches, safeguarding distribution equipment and ensuring reliable power distribution.

Epoxy resin support insulators emerge as indispensable components ensuring the safety of distribution equipment, including distribution cabinets, circuit breakers, switch cabinets, and isolation switches. This section sets the stage for a comprehensive exploration of these insulators, emphasizing their pivotal role in supporting the infrastructure of power distribution.

Historical Evolution: Shifting from Ceramic to Epoxy Resin Insulators

The evolution of insulator materials marks a significant shift from traditional ceramic to modern epoxy resin. This paragraph delves into the historical context, highlighting the past reliance on ceramic insulators and the transformative introduction of epoxy resin insulators. The evolution reflects advancements in manufacturing techniques and a commitment to enhancing the safety and efficiency of distribution equipment.

Lichang Industrial Co., Ltd.: Pioneering Excellence in Epoxy Resin Insulation

Japan’s Lichang Industrial Co., Ltd. takes center stage as a pioneer in the field of epoxy resin insulation. Since 1974, the company has been utilizing the pressure solidification method to manufacture indoor insulators with a focus on quality consistency. This section explores Lichang Industrial’s contribution to setting industry standards and shaping the trajectory of epoxy resin insulation technology.

Manufacturing Mastery: The Pressure Solidification Method Unveiled

The pressure solidification method serves as a cornerstone in the manufacturing process of epoxy resin support insulators. This paragraph delves into the intricacies of this method, explaining how it ensures quality consistency in the production of insulators. The emphasis is on the role of pressure solidification in creating robust and reliable insulators for indoor applications.

Advantages of Epoxy Resin: A Shift Towards Efficiency and Safety

Exploring the benefits of epoxy resin insulators, this section elaborates on their advantages over traditional ceramic counterparts. The utilization of epoxy resin allows for deeper twists in the insulator’s curved surface, ultimately extending the insulation distance. The result is a reduction in both weight and volume, making epoxy resin insulators more compact and efficient compared to their ceramic counterparts at the same voltage.

Weight and Volume Efficiency: Redefining Insulator Design with Epoxy Resin

The weight and volume efficiency of epoxy resin insulators represents a paradigm shift in insulator design. This paragraph delves into the practical implications of this efficiency, emphasizing how it translates to more compact and lightweight insulators. The comparison with ceramic insulators at the same voltage underscores the transformative impact of epoxy resin in redefining the physical characteristics of insulating materials.

Deeper Twists and Insulation Distance: Engineering Innovation in Epoxy Resin Insulators

The engineering innovation in epoxy resin insulators is spotlighted through the capability of deeper twists in the insulator’s design. This innovation is not merely aesthetic but holds functional significance by extending the insulation distance. This section explores how the curved surface of epoxy resin insulators contributes to enhanced safety and performance in power distribution applications.

Gaoyi United: Pioneering Professionalism in Epoxy Resin Insulation

Gaoyi United emerges as a stalwart in the field of epoxy resin insulation, positioned as professional pioneers. This paragraph introduces Gaoyi United’s commitment to excellence in manufacturing epoxy resin support insulators. The company’s role in advancing the technology and application of epoxy resin insulation further reinforces its position as a leader in the industry.

Practical Applications: Safeguarding Distribution Equipment with Epoxy Resin Support Insulators

Shifting focus to practical applications, this section explores how epoxy resin support insulators play a vital role in safeguarding distribution equipment. From distribution cabinets to circuit breakers and isolation switches, these insulators form a critical layer of protection, ensuring the reliable and secure operation of power distribution systems.

The Future Landscape: Epoxy Resin Insulators as Catalysts for Change

The exploration concludes by contemplating the future landscape shaped by epoxy resin insulators. Their continued advancements and adoption in the industry position them as catalysts for change, driving innovation and efficiency in power distribution systems. The transformative journey from ceramic to epoxy resin insulators reflects a trajectory towards a safer, more reliable, and technologically advanced power infrastructure.

Related Products