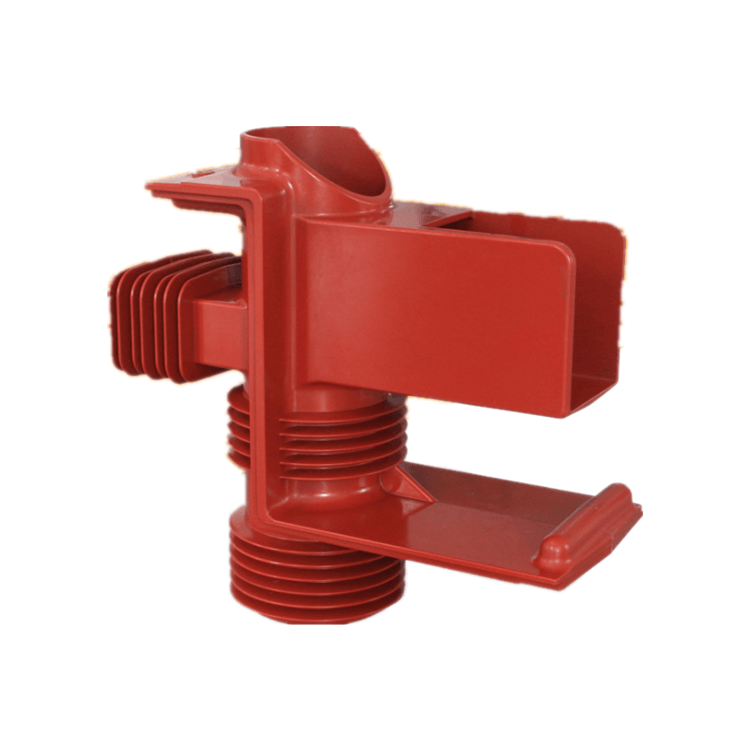

Epoxy Resin Sensor Insulator: A Comprehensive Knowledge-Based Guide

Introduction

Epoxy resin sensor insulators are essential components in various industries, providing a critical link between sensors and the surrounding environment. Their importance lies in offering protection to sensitive sensors while ensuring accurate data acquisition. This comprehensive article explores epoxy resin sensor insulators in detail, covering their construction, properties, applications, and advantages.

Construction and Materials

Epoxy resin sensor insulators are typically constructed using a combination of epoxy resins and various reinforcing materials. The choice of materials is crucial, as it affects the insulator’s electrical, mechanical, and thermal properties.

- Epoxy Resin: Epoxy resins are chosen for their exceptional electrical insulation properties, chemical resistance, and mechanical strength. They provide a durable encapsulation for the sensor.

- Reinforcing Materials: Reinforcements like glass fibers, aramid fibers, or carbon fibers may be added to enhance mechanical strength and dimensional stability. The choice of reinforcement depends on the specific application and the desired properties.

- Fillers and Additives: Fillers and additives can be incorporated into the epoxy resin mixture to further tailor the insulator’s characteristics. Examples include flame retardants for fire resistance and conductive fillers for shielding against electromagnetic interference (EMI).

Properties of Epoxy Resin Sensor Insulators

Epoxy resin sensor insulators exhibit a range of properties that make them suitable for diverse applications:

- Electrical Insulation: Epoxy resins offer excellent dielectric properties, preventing electrical conduction between the sensor and its surroundings. This property is critical for sensors operating in electrical environments.

- Mechanical Strength: The addition of reinforcing materials significantly enhances the insulator’s mechanical strength, ensuring it can withstand physical stress and protect the sensor.

- Chemical Resistance: Epoxy resins are resistant to many chemicals, safeguarding the sensor from corrosive or reactive substances.

- Temperature Resistance: Epoxy resin insulators can withstand a wide range of temperatures, making them suitable for both high- and low-temperature environments.

- Dimensional Stability: The choice of reinforcing materials and proper curing processes ensures that epoxy resin insulators maintain their shape and dimensions over time.

- Low Water Absorption: They have low water absorption rates, making them suitable for applications where moisture resistance is crucial.

Applications

Epoxy resin sensor insulators find applications in various industries and environments due to their versatile properties:

- Electrical Engineering: In this domain, these insulators are used to encapsulate and protect sensors in transformers, circuit breakers, and other electrical equipment. Their excellent electrical insulation properties are essential in preventing short circuits and maintaining the integrity of the sensor data.

- Aerospace: Epoxy resin insulators are used in aircraft and spacecraft to protect sensors from the extreme conditions of high altitudes, rapid temperature changes, and exposure to radiation.

- Industrial Automation: Sensors used in manufacturing and industrial automation often require protection against dust, chemicals, and mechanical stress. Epoxy resin sensor insulators ensure the longevity and reliability of these sensors.

- Environmental Monitoring: Environmental sensors used for weather forecasting, pollution monitoring, and climate studies are often exposed to harsh outdoor conditions. Epoxy resin insulators protect them from moisture, UV radiation, and temperature fluctuations.

- Medical Devices: In medical applications, sensors used for patient monitoring and diagnostic equipment benefit from the biocompatible nature of epoxy resin insulators, which prevent adverse reactions when in contact with human tissues.

Advantages of Epoxy Resin Sensor Insulators

Epoxy resin sensor insulators offer several advantages over alternative materials and encapsulation methods:

- Versatility: They can be customized to meet specific requirements, making them suitable for a wide range of applications.

- Longevity: Epoxy resin insulators are known for their durability and resistance to environmental factors, ensuring a long service life for the protected sensors.

- High Dielectric Strength: They provide a high dielectric strength, preventing electrical breakdown and ensuring the accuracy of sensor measurements.

- Ease of Installation: Epoxy resin insulators are relatively easy to install, simplifying the integration of sensors into various systems.

- Cost-Effective: Their long lifespan and low maintenance requirements make them cost-effective in the long run.

Maintenance and Care

Proper maintenance and care are essential to ensure the continued functionality of epoxy resin sensor insulators. Regular inspections, cleaning, and potential re-encapsulation are necessary to address any damage or degradation over time.

Conclusion

Epoxy resin sensor insulators are indispensable components in modern engineering and technology, safeguarding sensitive sensors across a broad spectrum of applications. Understanding their construction, properties, applications, and advantages is vital for professionals working in fields that rely on accurate and reliable sensor data. The versatility and durability of epoxy resin insulators continue to drive innovation in sensor technology, enabling new possibilities in industries ranging from aerospace to healthcare.