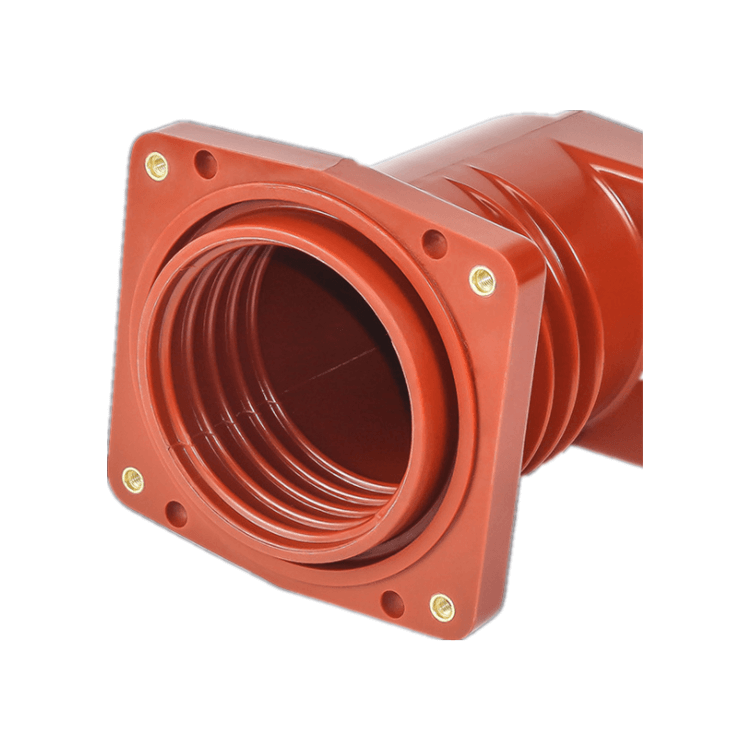

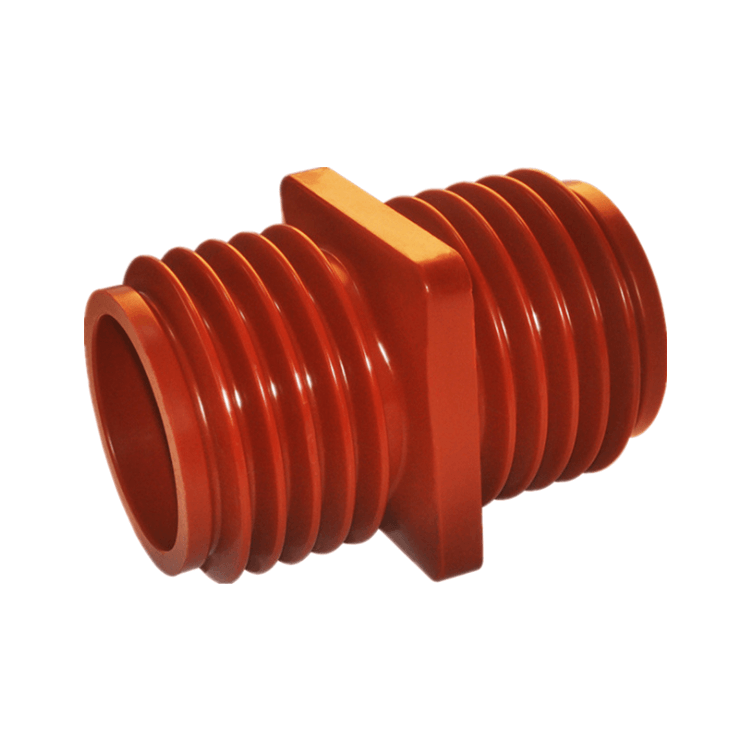

Epoxy Insulators

- Home

- >

- Epoxy Insulators

- >

- Page 10

Categories

News

What is an epoxy resin insulator?

Epoxy resin insulator is a common power equipment. It is mainly used in high-voltage electrical equipment in power systems, such as transformers, circuit breakers, isolating switches, etc. Epoxy resin insulators have excellent insulation properties, mechanical strength and Weather resistance, so it is widely used in power systems.

The main material of epoxy resin insulators is epoxy resin, which is a polymer compound with excellent insulation properties and mechanical strength. The manufacturing process of epoxy resin insulators mainly includes mold manufacturing, epoxy resin injection molding, curing and Surface treatment and other steps. During the manufacturing process, the process parameters of each link need to be strictly controlled to ensure the quality and performance of the insulator. Epoxy resin type insulators have many advantages. First, it has excellent insulation properties and can effectively prevent electrical Failures such as leakage and breakdown occur in the equipment. Secondly, it has high mechanical strength and durability and can withstand large mechanical stress and environmental impact. In addition, epoxy resin insulators also have good weather resistance and corrosion resistance. It is durable and can maintain good performance in harsh environments!

They can be used in a variety of indoor and outdoor applications such as switchgear bus supports, transformers, poles and other special electrical equipment. Isolation insulators should be designed and tested to comply with electrical and mechanical industry standards, including ANSI, IEEE, IEC and NEMA.

When selecting insulators for your project, there are several important design requirements to consider:

Application, where and how the insulation is used and installed, including environmental factors such as pollution, ambient temperature and UV exposure.

Voltage level

Mechanical strength requirements

Since the primary function of an isolation insulator is mechanical support, mechanical ratings must be primarily considered, such as:

Cantilever Strength – The weight that a wall-mounted insulator will support when an object is hung from it.

Tensile Strength – The amount of stress an insulator will experience when pressure is applied to pull directly upward on the bolt in the insert.

Torsional Strength – The amount of stress an insulator can withstand when torque is applied to twist it.

Compressive Strength – The weight an insulator can support when direct vertical pressure is applied.

The most common insulator classes are A20 and A30 (describing mechanical strength). Depending on project requirements, Polycast also offers insulators in other mechanical strength grades.

Installation configuration

Epoxy standoff insulators feature an integrally cast threaded metal insert for mounting to a cabinet or wall. To accommodate various applications, thread sizes, mounting configurations, and metal materials used vary.

Dimensional control of height and creep

Insulator height determines the distance between the voltage source and ground or other components.

Creep (leakage) distance is the shortest distance on the surface of an insulator between two conductive parts. Creep occurs when contaminants accumulate on the surface of an insulator and provide a conductive path for electrical current. It can be controlled by the design of the shed and shape of the insulator, for example, a deep shed design provides greater creepage distance.

Materials used

Depending on the application requirements, various types of insulation materials can be used, such as epoxy, glass and ceramic. Epoxy resin has advantages over other materials because:

Epoxy insulators are highly resistant to physical impact and will not shatter when subjected to thermal or mechanical forces. They also have very high electrical breakdown strength.

Epoxy resin is homogeneous. If the surface is damaged, the underlying material can provide the same properties.

Epoxies are economical even at lower volumes

GAOYI offers a variety of indoor and outdoor epoxy isolation insulators with rated voltages up to 46kV/250kV BIL, suitable for various strength levels. All insulators are designed and manufactured to meet and exceed North American and international standards.

Indoor epoxy insulation has an operating temperature range of -25°C to +95°C. Outdoor epoxy insulators can withstand temperatures from -50°C to +95°C and are recommended for applications where UV, pollution or condensation are a concern. Our materials are UL 94 V0 certified.

The GAOYI engineering team is always developing new insulation equipment to meet your unique needs. Our rigorous manufacturing processes allow us to respond quickly to customer requirements and emergency requests, including the design and mold fabrication of new insulators.