INDIAN ELECTRICAL INDUSTRY

The Indian electrical equipment industry experienced a 11.25% growth in 2009-10, compared to a 2.73% increase in the previous year. The sector’s growth was driven by economic recovery in real estate and infrastructure, with sectors like rotating machines, switchgear, and cables experiencing growth rates exceeding 30%. The switchgear sector saw the highest growth, with 14.54%. The cable industry experienced 12% growth, with the power cable segment leading the charge. The building wire segment experienced improved demand dynamics, while the transformer sector saw 9% growth.

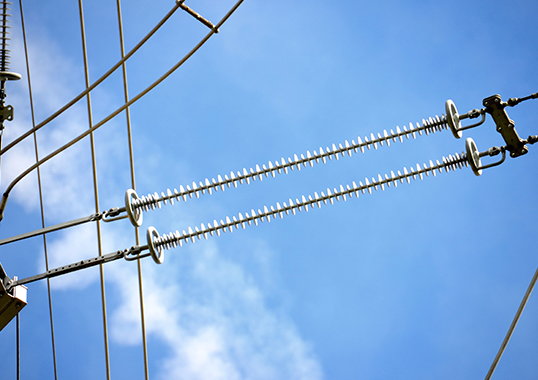

WHAT DOES THE BUSBAR INSULATOR DO?

Standoff Busbars are crucial components in electrical infrastructure, providing support, insulation, and fixation for current-carrying conductors. They are made of insulating materials, such as magnetic and porcelain, and are designed to provide mutual insulation between the busbar and surrounding metal components. The cylindrical form and presence of screw rods at both ends contribute to their design intricacies. The primary function of insulators is to insulate and fix current-carrying conductors, including busbars and wires. Their versatility and adaptability make them essential components in various electrical setups.

Why choose us? Gaoyi United Insulator well-known factory-type enterprise

Gaoyi United, a national high-tech enterprise, is a trusted name in insulator manufacturing. Established in 2005, the company focuses on research and development, with over 30% of its employees dedicated to R&D initiatives. Gaoyi United Insulator is a well-known factory-type enterprise with over 100 core manufacturing and invention patents, showcasing its expertise in innovation. With a strong R&D team, intellectual property portfolio, and commitment to delivering exceptional products, Gaoyi United is a trusted partner in providing innovative and high-quality insulator solutions.

Epoxy Resin Support Insulator

Epoxy resin support insulators are crucial for ensuring the safety and efficiency of distribution equipment, supporting power infrastructure. Japan’s Lichang Industrial Co., Ltd. has been leading the way since 1974 using the pressure solidification method. The manufacturing mastery in epoxy resin insulators, particularly the pressure solidification method, ensures quality consistency. Advantages of epoxy resin include deeper twists in the insulator’s curved surface, making them more compact and lightweight. Gaoyi United is a professional pioneer in the field, contributing to the advancement of epoxy resin insulation technology.

Busbar Insulator Low Voltage Standoff Isolator for Switchgear

This section explores the role of busbar insulators in switchgear, focusing on their versatility and importance in ensuring the efficiency and safety of electrical systems. Busbar insulators are crucial for insulation isolation and transitions within electrical equipment, and their manufacturing process involves precision and skill. Quality control is a crucial phase, with rigorous testing protocols aligned with national standards. These insulators are versatile, integrating into power distribution systems and industrial machinery, contributing to efficiency and safety. They are a cornerstone of switchgear systems.

What is an insulated contact box

Gaoyi United’s High Voltage Sensor Insulator is a crucial component in industrial practices, serving as a pressure sensor in dynamic environments. These insulators are cast with epoxy resin, offering high strength, robust arc resistance, and minimal partial discharge. Gaoyi United has 12 years of expertise in insulation technology and offers a comprehensive range of insulation solutions, including hot insulators/clamps. The company’s competitive edge includes 12 years of professional production experience, an annual production capacity of 10 million, a dedicated R&D team, and certifications like CE, REACH, and SGS-ROHS.

Process for the production of insulators

The production of insulators involves several steps, including material measurement, heating the mold for precision, placing the insert in the mold, introducing the insulator material, sealing the deal, pressing the material, deburring the insulator, preparing for departure, and packing the insulator. These steps are crucial for maintaining the integrity of electrical systems and ensuring safety and efficiency. The process begins with weighing the material, then involves heating the mold, placing the insert in the mold, introducing the insulator material, sealing the deal, pressing the insulator, refining the insulator, and packing the insulator.

The application of the insulators

Insulators are essential products in electrical systems, ensuring reliability and safety in overhead transmission lines. Historically used on electric telegraph poles, they now play a significant role in high and low voltage equipment. Insulators are categorized by voltage, with high-voltage insulators being crucial in powering transmission lines and substations. They can be customized to meet specific voltage needs, and their versatility extends beyond transmission lines to high and low voltage systems. Insulator technology advancements are expected to further enhance efficiency and effectiveness in electrical systems.

What does a standoff busbar consist of?

CPI Standard Busbars are specialized insulated ground bus mounting plates designed for commercial applications, featuring Hard-Drawn Electrolytic Tough Pitch 110 Alloy solid copper bonding bars. These busbars come in various configurations, including 10″ for 1/4″ single bolt lugs, 12″ and 20″ for nine or 17 lugs, and 3/8″ bolts. The assembly includes essential components like insulators, stand-off brackets, stainless steel bolts, lock washers, and flat washers, all shipped individually and preassembled for convenience. The material composition of the busbars is a key consideration, ensuring structural integrity and space efficiency in electrical systems.