Cast Resin Bushing Explained

Introduction

Cast resin bushings are vital components in various electrical and power distribution systems, providing insulation and support for conductors. These specialized insulating devices play a crucial role in ensuring the reliable and safe transmission of electrical power across different voltage levels. In this comprehensive article, we will delve into the intricacies of cast resin bushings, exploring their design, applications, manufacturing process, and key advantages.

Understanding Cast Resin Bushings

What Are Cast Resin Bushings?

Cast resin bushings, also known as dry-type bushings, are electrical insulators used to connect transformers, switchgear, and other electrical equipment to external conductors, while providing electrical insulation and mechanical support. They are primarily used in medium to high voltage applications, typically ranging from 1 kV to 52 kV, and serve to prevent electrical discharges and protect the surrounding environment.

Design and Construction

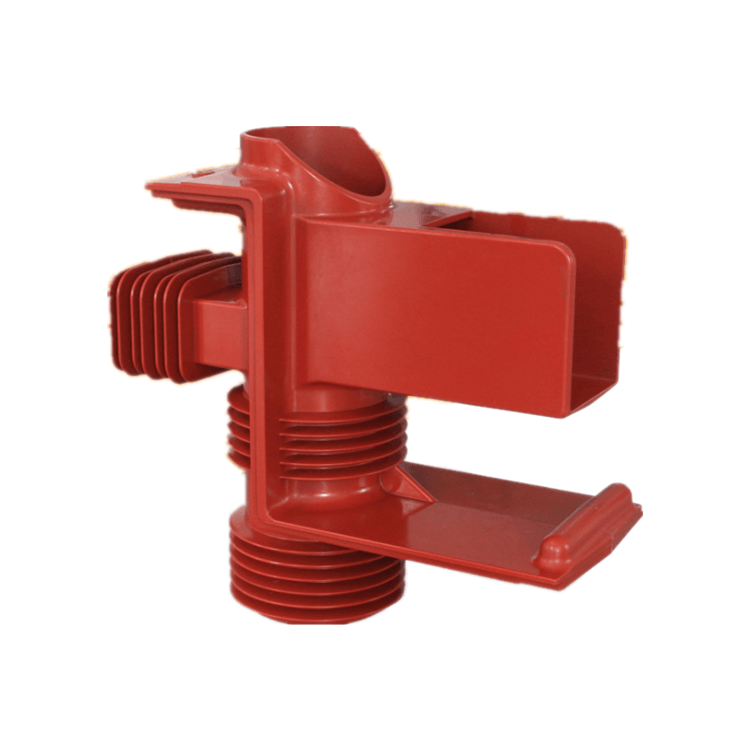

Cast resin bushings are designed to withstand various electrical, thermal, and mechanical stresses in demanding environments. They consist of several key components:

1. Resin Insulator Core:

- The core of a cast resin bushing is typically made of epoxy or silicone-based resin. These resins offer excellent electrical insulation properties and can endure high temperatures without losing their dielectric strength.

2. Conductive Inserts:

- Embedded within the resin core, conductive inserts, often made of aluminum, copper, or other metals, provide a path for electrical current and ensure a secure connection to the conductor.

3. Flanges and Mounting Hardware:

- Cast resin bushings are equipped with flanges and mounting hardware to securely attach them to the equipment and maintain structural integrity.

4. Insulating Sheds:

- The exterior of the bushing is designed with insulating sheds or skirts to create a smooth surface and reduce the risk of flashovers, especially in polluted or wet environments.

Manufacturing Process

The manufacturing of cast resin bushings involves several precise steps:

- Core Fabrication: The resin core is produced using a vacuum casting process, which ensures uniformity and void-free construction. The core may also include pre-shaped conductor inserts.

- Assembly: The insulating sheds are attached to the core, and the flanges and mounting hardware are added.

- Curing: The entire assembly is cured in an oven, allowing the resin to harden and achieve its final structural integrity.

- Testing: Stringent quality control tests, including partial discharge, impulse, and AC withstand tests, are performed to ensure the bushing’s electrical integrity.

Applications of Cast Resin Bushings

Transformers

Cast resin bushings are commonly used in both distribution and power transformers. They provide electrical insulation between the high-voltage windings and the transformer tank, ensuring safe and efficient power transfer.

Switchgear

In medium and high voltage switchgear, cast resin bushings play a critical role in connecting the switchgear to external conductors, maintaining the integrity of the insulation barrier, and preventing electrical flashovers.

Circuit Breakers

Circuit breakers, particularly in medium voltage systems, benefit from cast resin bushings to maintain insulation and facilitate electrical connections.

Cable Terminations

In cable terminations, cast resin bushings act as a link between underground power cables and above-ground electrical equipment, ensuring a safe and efficient transfer of power.

Advantages of Cast Resin Bushings

1. Pollution Resistance

Cast resin bushings are highly resistant to pollution and provide superior performance in contaminated and humid environments. The design of insulating sheds helps prevent the accumulation of dirt and dust, reducing the risk of flashovers.

2. Minimal Maintenance

Unlike oil-filled bushings, cast resin bushings require minimal maintenance, as they do not necessitate regular oil monitoring and refilling. This characteristic makes them a cost-effective and low-maintenance choice for many applications.

3. Excellent Dielectric Properties

The epoxy or silicone-based resins used in cast resin bushings offer exceptional dielectric properties, ensuring reliable insulation even in demanding conditions.

4. Fire Safety

Cast resin bushings are inherently fire-resistant, which is a significant advantage in applications where fire safety is a concern.

5. Environmental Friendliness

These bushings are eco-friendly as they do not contain oil, making them a sustainable choice for modern power distribution systems.

Conclusion

Cast resin bushings are integral components in electrical systems, offering robust insulation and mechanical support. Their unique design, manufacturing process, and numerous advantages make them a preferred choice in various medium to high voltage applications. Whether in transformers, switchgear, circuit breakers, or cable terminations, cast resin bushings play a crucial role in ensuring the safe and reliable transmission of electrical power. Understanding the intricacies of these bushings is essential for engineers, technicians, and professionals working in the field of electrical power distribution.