Blogs

- Home

- >

- Blogs

- >

- Page 2

Process for the production of insulators

The production of insulators involves several steps, including material measurement, heating the mold for precision, placing the insert in the mold, introducing the insulator material, sealing the deal, pressing the material, deburring the insulator, preparing for departure, and packing the insulator. These steps are crucial for maintaining the integrity of electrical systems and ensuring safety and efficiency. The process begins with weighing the material, then involves heating the mold, placing the insert in the mold, introducing the insulator material, sealing the deal, pressing the insulator, refining the insulator, and packing the insulator.

The application of the insulators

Insulators are essential products in electrical systems, ensuring reliability and safety in overhead transmission lines. Historically used on electric telegraph poles, they now play a significant role in high and low voltage equipment. Insulators are categorized by voltage, with high-voltage insulators being crucial in powering transmission lines and substations. They can be customized to meet specific voltage needs, and their versatility extends beyond transmission lines to high and low voltage systems. Insulator technology advancements are expected to further enhance efficiency and effectiveness in electrical systems.

What does a standoff busbar consist of?

CPI Standard Busbars are specialized insulated ground bus mounting plates designed for commercial applications, featuring Hard-Drawn Electrolytic Tough Pitch 110 Alloy solid copper bonding bars. These busbars come in various configurations, including 10″ for 1/4″ single bolt lugs, 12″ and 20″ for nine or 17 lugs, and 3/8″ bolts. The assembly includes essential components like insulators, stand-off brackets, stainless steel bolts, lock washers, and flat washers, all shipped individually and preassembled for convenience. The material composition of the busbars is a key consideration, ensuring structural integrity and space efficiency in electrical systems.

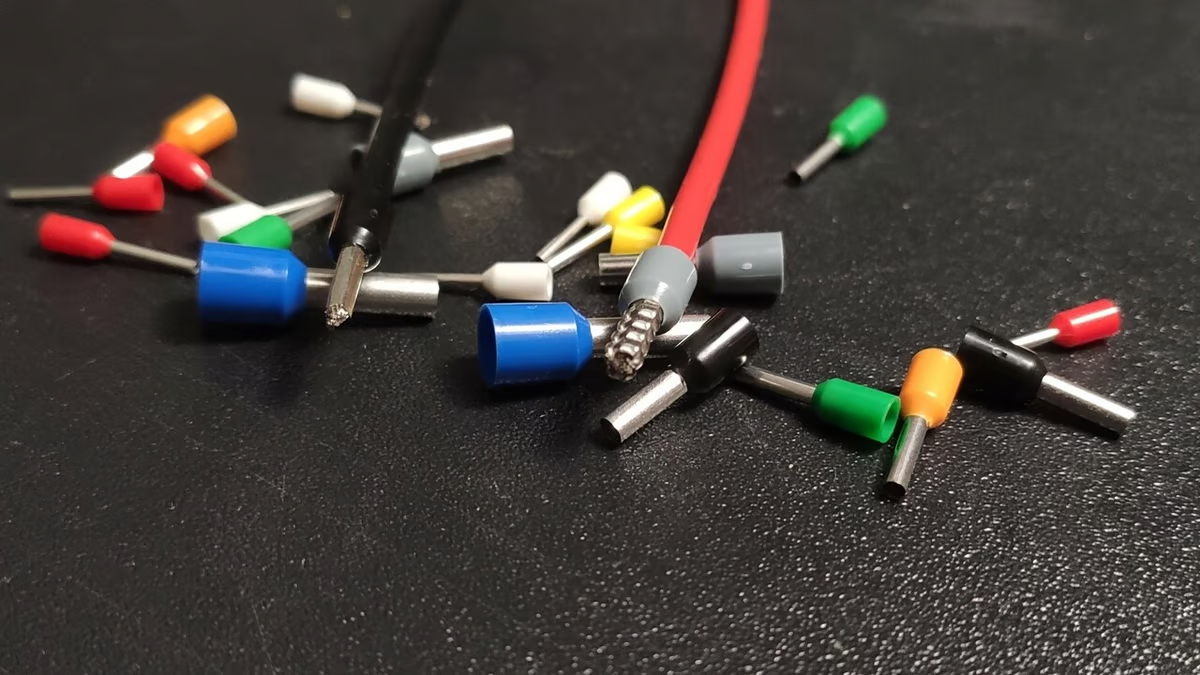

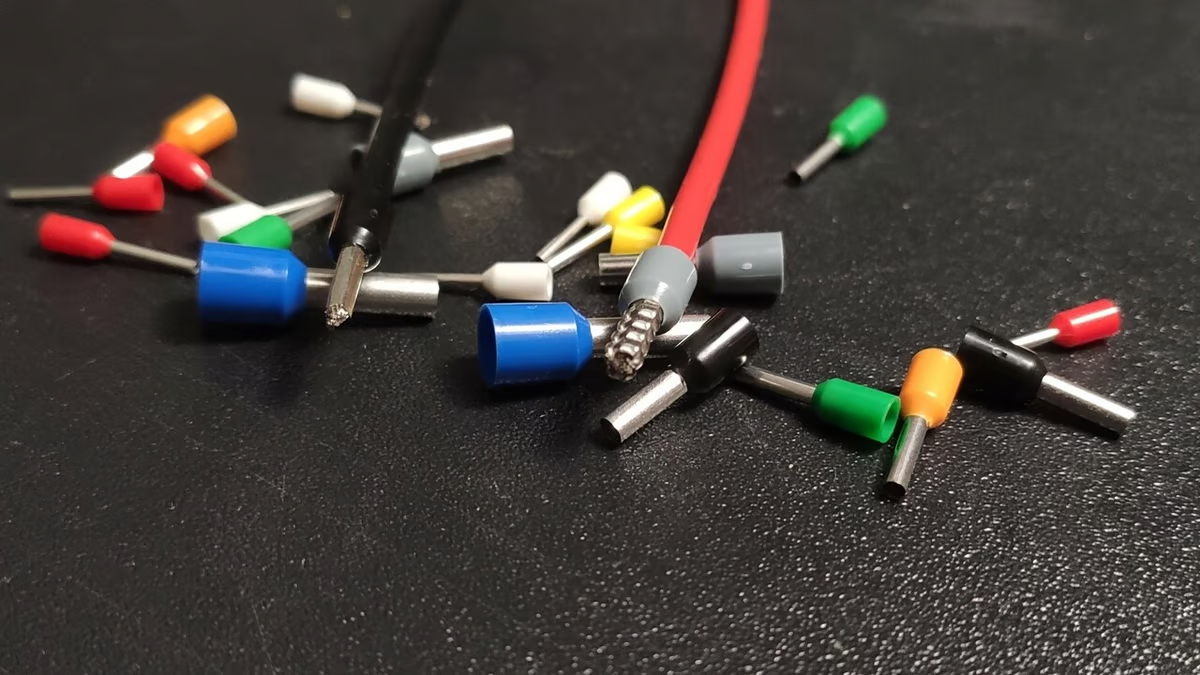

THE DIFFERENT TYPES OF WIRE CONNECTORS AND THEIR USES

Wire connectors are essential components in electrical systems, securing two or more wires together for electricity transfer and communication. There are various types, including twist-on wire connectors, crimp connectors, solder connectors, and screw connectors. Twisted wire connectors are made of plastic, crimped onto wires, solder connectors melt solder onto wires, and screw connectors are used for strong, permanent connections. It’s crucial to choose the right connector for your application to avoid issues like loose connections or fire hazards.

EL Low-High Insulators Gaoyi United Rail Insulators Spacer Insulators

Insulated bus supports are essential components in electrical systems, securely holding live electrical conductors. They play a crucial role in various applications, including high-voltage to low-voltage switchgear and controlgear assemblies. These systems, characterized by solid insulation between conductors and ground, are used in switchgear, switchboards, and busway installations. Insulated copper conductors enhance designs by minimizing circuit footprints, reducing turning radii, and eliminating creepage and clearance issues. Ongoing innovations in busbar support technology contribute to the efficiency and reliability of electrical systems. Safety considerations are crucial in busbar systems.

Your Reliable Electrical Insulation Manufacturer and Supplier

In the quest for a trustworthy manufacturer and supplier of electrical insulation solutions, prioritize reliability, innovation, and consistency. Seek a partner with a proven track record in delivering high-quality products that meet industry standards and embrace cutting-edge technologies. Effective communication and responsive customer support are crucial elements, fostering a relationship built on trust. Ensure the chosen supplier holds relevant certifications and complies with industry regulations to guarantee product safety and quality. The ability to customize solutions based on unique requirements showcases a supplier’s flexibility and commitment to meeting customer expectations.

Process for the production of insulators

The production of insulators involves several steps, including material measurement, heating the mold for precision, placing the insert in the mold, introducing the insulator material, sealing the deal, pressing the material, deburring the insulator, preparing for departure, and packing the insulator. These steps are crucial for maintaining the integrity of electrical systems and ensuring safety and efficiency. The process begins with weighing the material, then involves heating the mold, placing the insert in the mold, introducing the insulator material, sealing the deal, pressing the insulator, refining the insulator, and packing the insulator.

The application of the insulators

Insulators are essential products in electrical systems, ensuring reliability and safety in overhead transmission lines. Historically used on electric telegraph poles, they now play a significant role in high and low voltage equipment. Insulators are categorized by voltage, with high-voltage insulators being crucial in powering transmission lines and substations. They can be customized to meet specific voltage needs, and their versatility extends beyond transmission lines to high and low voltage systems. Insulator technology advancements are expected to further enhance efficiency and effectiveness in electrical systems.

What does a standoff busbar consist of?

CPI Standard Busbars are specialized insulated ground bus mounting plates designed for commercial applications, featuring Hard-Drawn Electrolytic Tough Pitch 110 Alloy solid copper bonding bars. These busbars come in various configurations, including 10″ for 1/4″ single bolt lugs, 12″ and 20″ for nine or 17 lugs, and 3/8″ bolts. The assembly includes essential components like insulators, stand-off brackets, stainless steel bolts, lock washers, and flat washers, all shipped individually and preassembled for convenience. The material composition of the busbars is a key consideration, ensuring structural integrity and space efficiency in electrical systems.

THE DIFFERENT TYPES OF WIRE CONNECTORS AND THEIR USES

Wire connectors are essential components in electrical systems, securing two or more wires together for electricity transfer and communication. There are various types, including twist-on wire connectors, crimp connectors, solder connectors, and screw connectors. Twisted wire connectors are made of plastic, crimped onto wires, solder connectors melt solder onto wires, and screw connectors are used for strong, permanent connections. It’s crucial to choose the right connector for your application to avoid issues like loose connections or fire hazards.

EL Low-High Insulators Gaoyi United Rail Insulators Spacer Insulators

Insulated bus supports are essential components in electrical systems, securely holding live electrical conductors. They play a crucial role in various applications, including high-voltage to low-voltage switchgear and controlgear assemblies. These systems, characterized by solid insulation between conductors and ground, are used in switchgear, switchboards, and busway installations. Insulated copper conductors enhance designs by minimizing circuit footprints, reducing turning radii, and eliminating creepage and clearance issues. Ongoing innovations in busbar support technology contribute to the efficiency and reliability of electrical systems. Safety considerations are crucial in busbar systems.

Your Reliable Electrical Insulation Manufacturer and Supplier

In the quest for a trustworthy manufacturer and supplier of electrical insulation solutions, prioritize reliability, innovation, and consistency. Seek a partner with a proven track record in delivering high-quality products that meet industry standards and embrace cutting-edge technologies. Effective communication and responsive customer support are crucial elements, fostering a relationship built on trust. Ensure the chosen supplier holds relevant certifications and complies with industry regulations to guarantee product safety and quality. The ability to customize solutions based on unique requirements showcases a supplier’s flexibility and commitment to meeting customer expectations.

Categories

News

-

Process for the production of insulators

10/13/2023 -

The application of the insulators

10/11/2023 -

What does a standoff busbar consist of?

10/09/2023