Introduction: Decoding the Essence of Busbar Insulators in Switchgear

Busbar insulators stand as linchpins in the realm of switchgear, providing crucial insulation isolation and facilitating transitions within various electrical equipment. This section sets the stage for an in-depth exploration of the low voltage standoff isolators, shedding light on their pivotal role in ensuring the efficiency and safety of electrical systems.

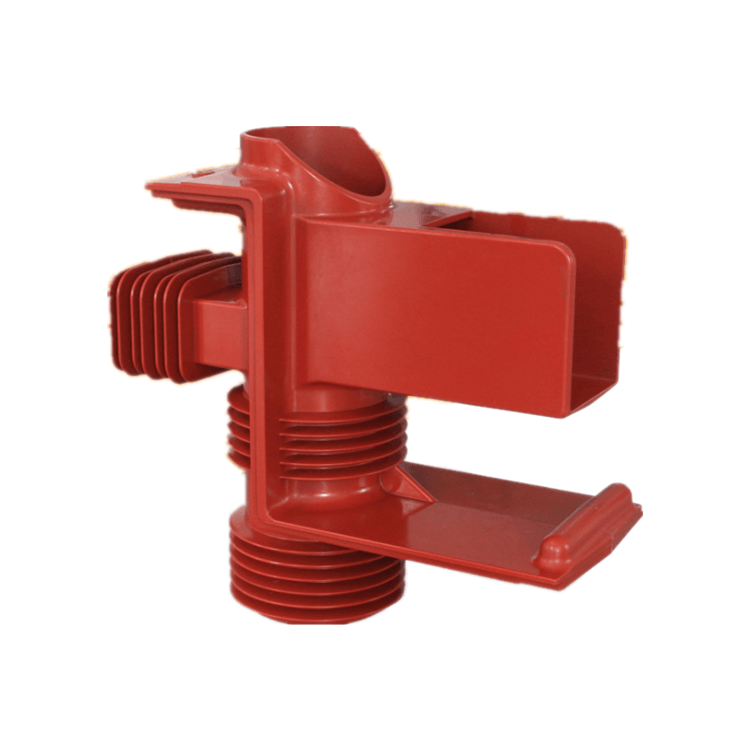

|

Material |

BMC |

|

Insert |

BRASS |

|

Dimension |

50*36 |

| Color |

RED,CUSTOMIZED |

| Torgue Strength | >25N.m |

| Rated Voltage | 660-4500V |

| Application | New energy,electrical industrial |

| Certification | CE,SGS,ROHS,ELV |

| Operating Temperature | -30℃~120℃ |

| Place of Origin | China |

The Crucial Link: Understanding the Role of Busbar Insulators

Delving into the foundational aspect, this paragraph unfolds the vital role that busbar insulators play in electrical equipment. Acting as the critical link for insulation isolation and transitions, these insulators are indispensable components in the intricate web of switchgear. Their significance becomes apparent as they contribute to the overall functionality and reliability of electrical systems.

Low Voltage Standoff Isolators: Navigating the Spectrum of Electrical Needs

The focus narrows down to the specific category of busbar insulators known as low voltage standoff isolators. This section explores the versatility of these isolators, elaborating on their capacity to address a spectrum of electrical needs. From low voltage applications to tailored insulation requirements, these isolators emerge as adaptable solutions within the switchgear landscape.

Manufacturing Marvel: The Craftsmanship Behind Busbar Insulators

Transitioning into the manufacturing realm, this paragraph unveils the craftsmanship involved in producing busbar insulators. The intricacies of the production process, aligned with the demands of switchgear applications, highlight the precision and skill required to create these essential components. The emphasis is on the meticulous approach to crafting insulators that meet stringent quality standards.

Quality Control: A Commitment to Excellence Post-Production

A crucial phase in the journey of busbar insulators is the post-production quality control process. This section delves into the commitment to excellence, where high-quality testing equipment such as voltage resistance and partial discharge testing come into play. The rigorous testing protocols, aligned with national standards, underscore the dedication to delivering products of the highest caliber.

Voltage Resistance: Ensuring Reliability under Electrical Stress

The integrity of busbar insulators under varying voltage conditions is paramount. This paragraph explores the role of voltage resistance testing in evaluating the insulators’ ability to withstand electrical stress without compromising their insulation properties. The adherence to national standards in this testing phase reinforces the commitment to delivering reliable and durable products.

Partial Discharge Testing: Unmasking Potential Weaknesses

The journey through quality control continues with a closer look at partial discharge testing. This testing method serves as a critical checkpoint, unveiling potential weaknesses in the busbar insulators. The meticulous approach to quality assurance ensures that any flaws or imperfections are identified and rectified, reinforcing the commitment to delivering insulators of uncompromised quality.

National Standards Compliance: A Pledge to Consistency and Safety

The commitment to adhering to national standards is a cornerstone of busbar insulator production. This paragraph delves into the significance of aligning with established standards, emphasizing the role it plays in ensuring consistency and safety across the spectrum of busbar insulators. Meeting and exceeding these standards is a testament to the dedication to quality and reliability.

Versatility in Application: Low Voltage Standoff Isolators in Action

Expanding on the real-world applications, this section showcases the versatility of low voltage standoff isolators. From power distribution systems to industrial machinery, these isolators seamlessly integrate into different electrical setups, contributing to the efficiency and safety of various operations. Their adaptability becomes evident as they stand as reliable components within diverse electrical landscapes.

The Switchgear Connection: Busbar Insulators as Guardians of Electrical Systems

Summing up the exploration, this paragraph reaffirms the significance of busbar insulators in the realm of switchgear. Whether ensuring insulation isolation or facilitating transitions, these insulators stand as guardians of reliability and safety in the complex web of electrical infrastructure. Their role in switchgear becomes a defining element in the seamless functionality of electrical systems.

Related Products