IEC (International Electrotechnical Commission) Standard Epoxy Resin Spout Insulators play a critical role in the electrical industry, particularly in high-voltage and medium-voltage applications. These insulators provide vital electrical insulation and mechanical support in various power transmission and distribution systems. In this detailed knowledge-based article, we will explore the intricacies of IEC Standard Epoxy Resin Spout Insulators, discussing their design, properties, applications, and the international standards that govern their production and use.

Section 1: Understanding IEC Standard Epoxy Resin Spout Insulators

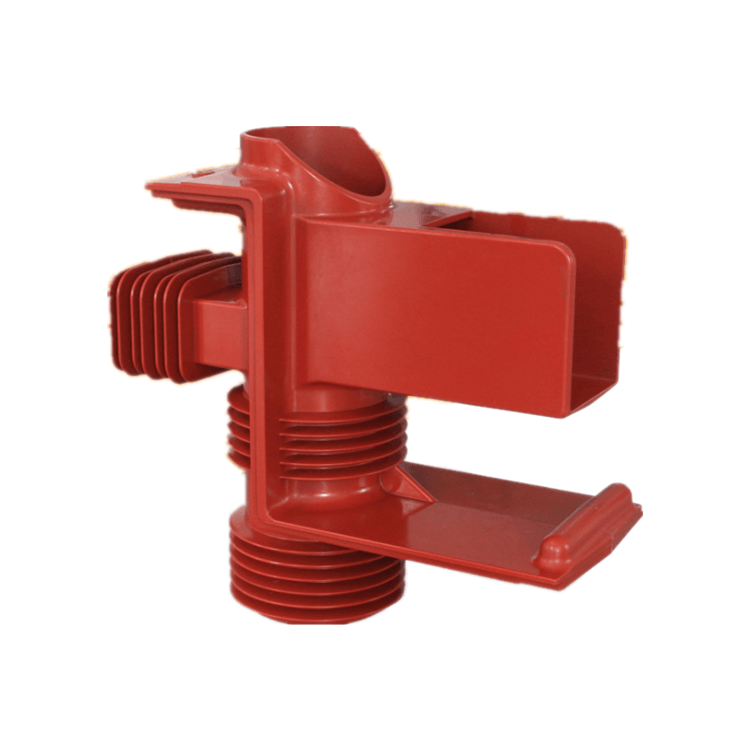

1.1 Definition and Purpose IEC Standard Epoxy Resin Spout Insulators are designed to insulate and support electrical conductors while withstanding electrical and environmental stresses. These insulators feature a specific design, characterized by a spout or nozzle-like structure.

1.2 Key Features IEC Standard Epoxy Resin Spout Insulators have several distinctive features:

- Epoxy Resin Material: These insulators are typically made of epoxy resin, which provides excellent electrical insulation properties and resistance to environmental factors, including UV radiation, moisture, and pollution.

- Spout Design: The spout design allows for enhanced electrical performance, as well as facilitating easy installation and maintenance.

- Mechanical Strength: Epoxy resin insulators possess high mechanical strength and can withstand various mechanical loads and stresses.

Section 2: Design and Manufacturing

2.1 Material Selection The selection of epoxy resin as the primary material for these insulators is crucial. Epoxy resin offers superior electrical and mechanical properties, making it an ideal choice for insulating and supporting conductors in demanding electrical systems.

2.2 Spout Design The unique spout design is a defining characteristic of these insulators. It aids in minimizing electrical stress and promoting a uniform electric field distribution along the insulator. The spout also serves as a barrier, preventing flashovers.

2.3 Manufacturing Process The manufacturing process involves several key steps:

- Epoxy Mixing: Raw epoxy resin is mixed with hardeners and additives to achieve the desired properties.

- Molding: The resin mixture is cast into molds, where it cures and hardens to form the insulator body.

- Spout Formation: The spout is created as an integral part of the insulator during the molding process.

- Quality Control: Stringent quality control measures are applied to ensure that each insulator meets IEC standards.

Section 3: Electrical Performance

3.1 Insulation Properties IEC Standard Epoxy Resin Spout Insulators exhibit excellent electrical insulation properties. They have a high resistance to leakage current and can withstand both wet and dry power frequency and lightning impulse voltage levels.

3.2 Flashover Resistance The spout design and epoxy resin material enhance the insulators’ ability to resist flashovers, even in polluted or contaminated environments.

Section 4: Applications

4.1 Power Transmission IEC Standard Epoxy Resin Spout Insulators find extensive use in power transmission systems. They are installed on transmission lines and substations to provide electrical insulation and mechanical support.

4.2 Distribution Systems These insulators are also used in medium-voltage distribution systems to support and insulate conductors, ensuring reliable electricity distribution.

4.3 Railway Electrification In railway electrification, epoxy resin insulators are employed to isolate overhead catenary wires, maintaining safe and uninterrupted train operations.

Section 5: International Standards

5.1 IEC 61109 Standard The IEC 61109 standard provides specifications and requirements for epoxy resin insulators, including those with spout designs. Compliance with this standard ensures the quality and performance of these insulators.

5.2 Regional Standards Different regions may have their own standards and regulations that govern the use of epoxy resin spout insulators. Manufacturers and utility companies must adhere to these standards to ensure safety and reliability.

Section 6: Maintenance and Testing

6.1 Routine Maintenance Regular inspection and cleaning of epoxy resin insulators are essential to prevent contamination and ensure their continued performance.

6.2 Electrical Testing Electrical testing, including flashover tests and leakage current measurements, helps assess the insulators’ health and performance.

6.3 Environmental Testing Epoxy resin insulators should undergo environmental testing to evaluate their resistance to UV radiation, pollution, and moisture.

Section 7: Conclusion

IEC Standard Epoxy Resin Spout Insulators are vital components in modern electrical systems. Their unique design and exceptional properties make them an excellent choice for electrical insulation and support in a variety of applications. Adherence to international standards ensures the quality and reliability of these insulators, making them a cornerstone of power transmission and distribution systems worldwide. As technology and materials continue to evolve, these insulators will play an ever more important role in maintaining the integrity and efficiency of our electrical infrastructure.