Epoxy Bushing vs. Porcelain Bushing: A Comprehensive Comparative Analysis

Introduction

Epoxy bushings and porcelain bushings are essential components in high-voltage electrical equipment and systems, providing electrical insulation and support for conductors and transformers. This detailed knowledge-oriented article explores the differences between epoxy and porcelain bushings, focusing on their materials, properties, advantages, disadvantages, and applications. Understanding the distinctions between these two types of bushings is crucial for making informed decisions in the design and maintenance of electrical power systems.

Material Composition

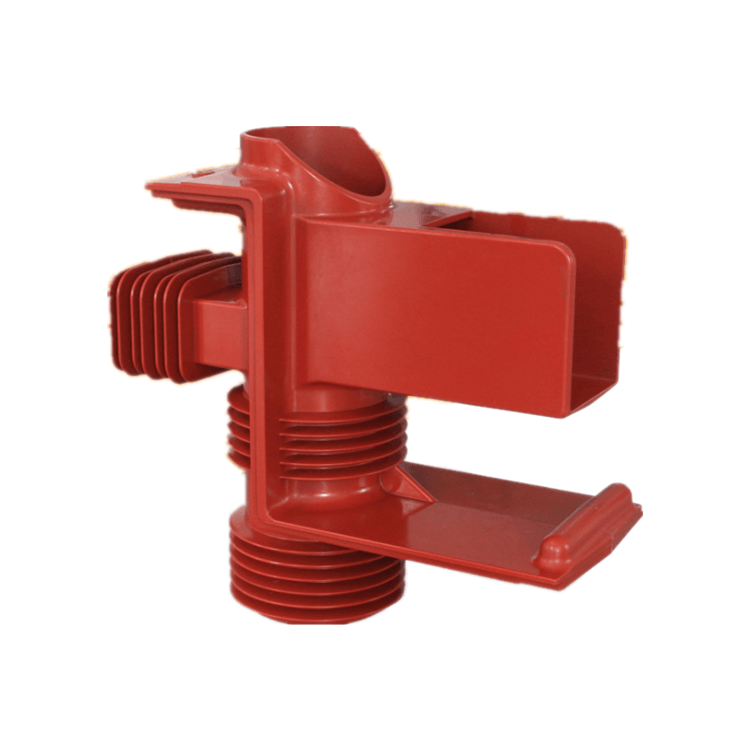

Epoxy Bushing

Epoxy bushings are manufactured using epoxy resin, a thermosetting polymer. This material exhibits excellent electrical insulation properties, mechanical strength, and resistance to environmental factors such as moisture and pollution. Epoxy resin bushings are typically reinforced with fiberglass or other materials to enhance their mechanical stability and performance.

Porcelain Bushing

Porcelain bushings, on the other hand, are made from high-quality ceramic materials. They are often composed of alumina (aluminum oxide) and clay, fired at high temperatures to form a solid and vitrified insulating structure. Porcelain is known for its durability and electrical insulating properties.

Electrical Properties

Epoxy Bushing

Epoxy bushings offer several advantages in terms of electrical properties:

- High dielectric strength: Epoxy resin has excellent dielectric properties, allowing it to withstand high electrical stresses without breaking down.

- Low electrical tracking and flashover: Epoxy’s hydrophobic nature and smooth surface reduce the risk of surface discharge or tracking even in polluted environments.

- Improved contamination performance: Epoxy bushings exhibit better contamination performance compared to porcelain, making them suitable for areas with high pollution levels.

Porcelain Bushing

Porcelain bushings also have noteworthy electrical properties:

- Excellent dielectric strength: Porcelain’s inherent insulating properties make it a reliable choice for high-voltage applications.

- High arc resistance: Porcelain’s robust nature makes it resistant to electrical discharges and arcs.

- Suitable for high-temperature applications: Porcelain bushings can withstand high operating temperatures without degrading their electrical performance.

Mechanical Properties

Epoxy Bushing

Epoxy bushings offer several mechanical advantages:

- Lightweight: Epoxy bushings are significantly lighter than porcelain, simplifying installation and transportation.

- Resistance to mechanical stress: The combination of epoxy and reinforcing materials provides high mechanical strength and resistance to vibrations and mechanical stresses.

- Lower risk of breakage: Epoxy’s flexibility and shock-absorbing properties reduce the risk of breakage during handling and service.

Porcelain Bushing

Porcelain bushings excel in mechanical aspects as well:

- Durability: Porcelain is exceptionally durable and resistant to mechanical impacts, making it suitable for outdoor and high-stress environments.

- Robustness: Porcelain’s rigid structure ensures long-term stability and reliability, even in harsh conditions.

- Higher vibration resistance: Porcelain bushings exhibit better vibration resistance compared to epoxy in certain applications.

Environmental Considerations

Epoxy Bushing

Epoxy bushings have specific environmental advantages:

- Resistance to pollution: Epoxy’s hydrophobic properties and smooth surface minimize the effects of pollution, making them suitable for polluted environments.

- UV resistance: Epoxy bushings are less susceptible to UV radiation degradation, extending their service life in outdoor applications.

Porcelain Bushing

Porcelain bushings have unique environmental considerations:

- Resistance to fire: Porcelain’s high-temperature tolerance and fire resistance make it a suitable choice for critical applications where fire safety is paramount.

- Stability in extreme conditions: Porcelain maintains its integrity in extreme temperature and weather conditions, including freezing cold and scorching heat.

Advantages and Disadvantages

Epoxy Bushing

Advantages of epoxy bushings:

- Lightweight and easy to handle.

- Low risk of breakage during handling.

- Excellent contamination performance.

- Suitable for polluted areas.

Disadvantages of epoxy bushings:

- Reduced mechanical robustness in certain situations.

- Limited suitability for high-temperature applications.

Porcelain Bushing

Advantages of porcelain bushings:

- Exceptional durability and long service life.

- Excellent mechanical strength.

- Superior resistance to high temperatures and fire.

- Suitable for high-voltage and extreme conditions.

Disadvantages of porcelain bushings:

- Heavier and more challenging to transport and install.

- Prone to breakage when subjected to mechanical stress.

Applications

Epoxy Bushing

Epoxy bushings find applications in various scenarios, including:

- Distribution transformers.

- High-pollution environments.

- Urban areas where weight and ease of handling are essential.

Porcelain Bushing

Porcelain bushings are commonly used in:

- High-voltage transformers and circuit breakers.

- Substations and power transmission lines.

- High-temperature and critical applications.

Conclusion

In the choice between epoxy bushings and porcelain bushings, it’s essential to consider specific application requirements, environmental factors, and performance expectations. Epoxy bushings are favored for their lightweight, contamination resistance, and suitability in polluted areas, while porcelain bushings excel in durability, high-temperature resistance, and extreme environmental conditions. Careful consideration of these factors is crucial in optimizing the reliability and performance of electrical power systems. Ultimately, the choice between epoxy and porcelain bushings depends on the specific needs and priorities of the application in question.