Epoxy is a versatile and widely used material with a broad range of applications in various industries. One crucial aspect of its utility is its thermal insulating properties. In this comprehensive article, we will delve into the question, “Is epoxy a good thermal insulator?” We will explore the science behind thermal insulation, examine the characteristics of epoxy as a thermal insulator, discuss its applications in different industries, and consider its advantages and limitations. By the end of this article, you will have a deep understanding of epoxy’s role as a thermal insulator.

Understanding Thermal Insulation

Thermal insulation is a crucial consideration in engineering and design across numerous industries. It involves the use of materials to reduce or control the transfer of heat between objects with different temperatures. Effective thermal insulation serves several purposes, including:

- Energy Efficiency: Proper insulation can significantly reduce energy consumption by maintaining desired temperatures within a system or structure.

- Temperature Control: Insulation helps maintain a consistent temperature, ensuring the comfort and safety of occupants in buildings and the efficient operation of industrial processes.

- Prevention of Heat Loss or Gain: Insulation minimizes heat transfer, preventing unwanted heat loss in cold environments or heat gain in hot environments.

- Condensation Control: Insulation helps prevent the formation of condensation, which can lead to corrosion, mold growth, and other problems.

Epoxy as a Thermal Insulator

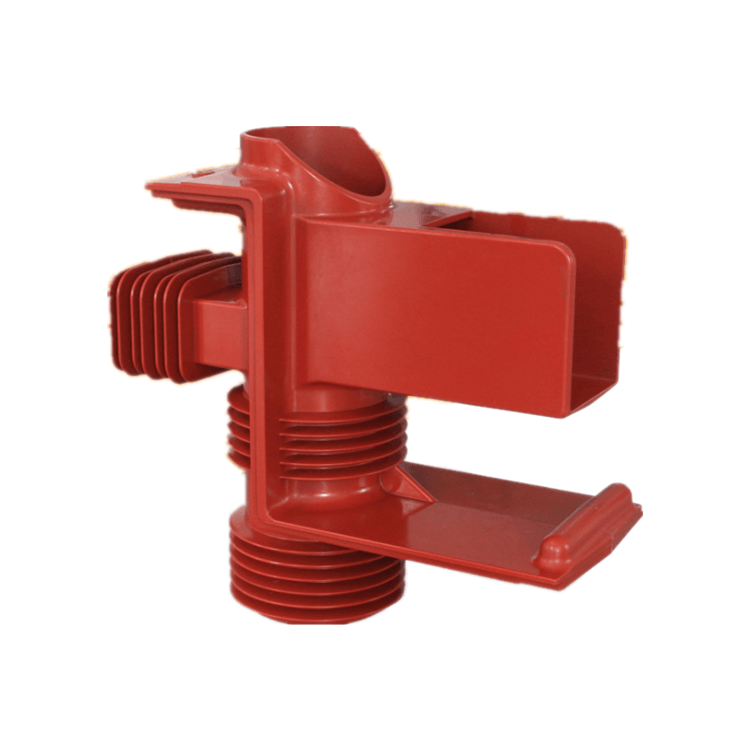

Epoxy resins are a class of thermosetting polymers known for their excellent electrical insulation properties and versatility. While they are not as commonly recognized for their thermal insulation capabilities as some other materials, epoxy can indeed serve as a thermal insulator in various applications. To understand its suitability, we must examine its thermal properties, such as thermal conductivity, heat capacity, and glass transition temperature.

- Thermal Conductivity: Epoxy generally has a low thermal conductivity, which means it is a poor conductor of heat. Its ability to resist heat transfer makes it a viable choice for thermal insulation. The thermal conductivity of epoxy can be further reduced by adding fillers or modifying its composition.

- Heat Capacity: Epoxy resins exhibit a relatively high heat capacity, meaning they can store and release heat when necessary. This property can be advantageous in applications where temperature fluctuations need to be minimized.

- Glass Transition Temperature (Tg): The glass transition temperature is a critical parameter for epoxy as a thermal insulator. Below its Tg, epoxy is in a glassy state, which generally enhances its insulating properties. Above Tg, it becomes more flexible and less effective as an insulator.

Applications of Epoxy as a Thermal Insulator

Epoxy’s thermal insulating properties find use in a variety of applications across different industries:

- Electronics: Epoxy resins are commonly used as encapsulants and potting compounds to protect electronic components from heat and moisture. Their low thermal conductivity helps in dissipating heat generated by electronic devices.

- Aerospace: Epoxy-based composites are employed in the aerospace industry to insulate and protect components from extreme temperature variations encountered during space missions.

- Construction: Epoxy-based insulation materials are used in building construction to provide thermal insulation in walls, roofs, and floors, improving energy efficiency and reducing heating and cooling costs.

- Industrial Equipment: Epoxy coatings are applied to industrial equipment to insulate them from high temperatures and prevent heat-related damage or wear.

- Automotive: Epoxy resins are used in the automotive industry for insulating electrical components and as adhesives for composite materials that require thermal stability.

Advantages of Epoxy as a Thermal Insulator

Epoxy offers several advantages as a thermal insulator:

- Low Thermal Conductivity: Epoxy’s low thermal conductivity effectively minimizes heat transfer.

- Electrical Insulation: Epoxy resins also provide excellent electrical insulation, making them suitable for applications that require both thermal and electrical insulation.

- Versatility: Epoxy can be tailored to specific needs through modifications and additives, enhancing its suitability for various applications.

- Chemical Resistance: Epoxy is resistant to many chemicals, making it suitable for harsh environments.

- Durability: Epoxy-based insulating materials are known for their long-lasting performance.

Limitations of Epoxy as a Thermal Insulator

While epoxy has many advantages as a thermal insulator, it also has limitations:

- Limited Temperature Range: Epoxy’s effectiveness as a thermal insulator is limited by its glass transition temperature (Tg). Above this temperature, its insulating properties decrease.

- Brittleness: Some epoxy formulations can be brittle, which may limit their use in applications where flexibility is required.

- Cost: High-quality epoxy materials can be relatively expensive, especially when compared to more traditional insulation materials.

- Environmental Considerations: The production and disposal of epoxy resins can have environmental impacts, which may be a concern in some applications.

Conclusion

In conclusion, epoxy can be a good thermal insulator in various applications, thanks to its low thermal conductivity and excellent electrical insulation properties. However, its suitability depends on specific requirements, including the operating temperature range, flexibility, and cost considerations. Epoxy’s versatility and durability make it a valuable choice for many industries seeking to manage heat and improve energy efficiency. Understanding the thermal properties of epoxy is essential for making informed decisions when selecting materials for insulation applications. While epoxy may not be the ideal thermal insulator in all scenarios, it remains a valuable tool in the engineer’s toolkit for managing heat and maintaining desired temperatures in various applications.