Understanding the Differences Between Porcelain and Epoxy Bushings in Electrical Systems

Introduction

In electrical power systems, the choice of insulating materials plays a critical role in ensuring safe and reliable operation. Bushings, which serve as essential components in power transformers, circuit breakers, and other electrical equipment, come in various materials, with porcelain and epoxy being two prominent options. This article delves into the key differences between porcelain and epoxy bushings, exploring their construction, electrical properties, environmental considerations, and application scenarios. By understanding these differences, engineers and professionals can make informed decisions when selecting the most suitable bushing for a specific electrical system.

Porcelain Bushings

Construction

Porcelain bushings have been used in electrical systems for many years and are known for their reliability. They are typically made from high-grade, glazed porcelain ceramic. The ceramic material is carefully molded and fired to create a robust and electrically insulating structure. Porcelain bushings often have a white or cream-colored appearance.

Electrical Properties

Porcelain bushings exhibit excellent electrical insulating properties, which makes them well-suited for medium to high voltage applications. They have high dielectric strength and low electrical conductivity, which effectively prevents current leakage. This characteristic is crucial in ensuring the safety and reliability of electrical systems, particularly in transformers and circuit breakers.

Environmental Considerations

One of the drawbacks of porcelain bushings is their susceptibility to environmental factors. They can be affected by pollution, humidity, and harsh weather conditions. Porcelain bushings may require periodic cleaning to prevent surface contamination, and in heavily polluted areas, additional pollution-resistant coatings may be applied. Additionally, porcelain bushings are relatively heavy, which can be a consideration in certain applications.

Applications

Porcelain bushings find applications in a wide range of electrical equipment, including power transformers, circuit breakers, and instrument transformers. They are commonly used in outdoor and indoor installations, particularly in medium and high voltage systems. Porcelain bushings are favored for their long history of reliability and suitability for various operating conditions.

Epoxy Bushings

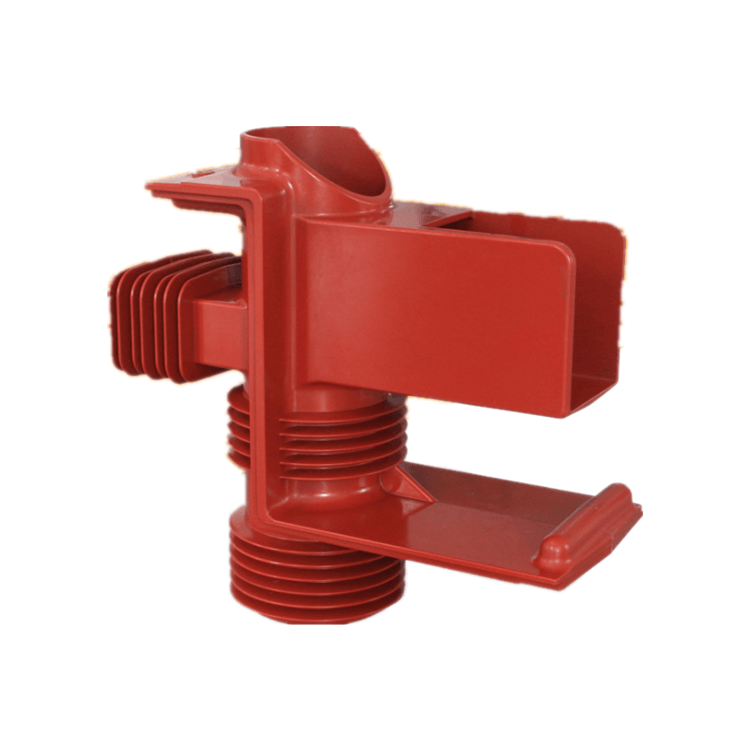

Construction

Epoxy bushings, on the other hand, are a relatively newer development in the field of electrical insulation. They are constructed using epoxy resin, which is cast and cured to form a solid and durable insulating structure. Epoxy bushings come in various shapes and sizes, and they are typically gray or brown in color.

Electrical Properties

Epoxy bushings are highly regarded for their excellent electrical insulation properties. They offer high dielectric strength and low electrical conductivity, making them suitable for medium and high voltage applications. Epoxy bushings can effectively withstand electrical stress, which is crucial for ensuring the safety and longevity of electrical equipment.

Environmental Considerations

Epoxy bushings are known for their resistance to environmental factors. They are inherently hydrophobic, which means they repel water and are less susceptible to surface contamination by pollutants. This property makes epoxy bushings particularly well-suited for outdoor installations, even in areas with high pollution levels. Epoxy bushings are also lightweight compared to porcelain, which can be advantageous in certain installations.

Applications

Epoxy bushings have gained popularity in various electrical equipment, especially transformers and circuit breakers. They are often used in outdoor applications where resistance to pollution and humidity is essential. The lightweight nature of epoxy bushings can also simplify handling and installation, making them an attractive choice in many scenarios.

Comparing Porcelain and Epoxy Bushings

To better understand the differences between porcelain and epoxy bushings, let’s summarize their distinctions:

Dielectric Strength

Both porcelain and epoxy bushings offer high dielectric strength, which is essential for preventing electrical breakdown. However, epoxy bushings are known for their ability to maintain dielectric strength in the presence of moisture and pollutants, making them a preferred choice for polluted environments.

Pollution Resistance

Porcelain bushings are more susceptible to pollution, requiring regular maintenance to clean the surface. Epoxy bushings, with their hydrophobic properties, are inherently more resistant to pollution, reducing the need for maintenance.

Weight

Epoxy bushings are significantly lighter than porcelain ones. This weight advantage simplifies transportation, handling, and installation, which can be crucial in certain situations.

Durability

Porcelain bushings have a long history of reliability, but they may require more maintenance in polluted environments. Epoxy bushings are durable and require less maintenance, making them a dependable choice, especially in challenging conditions.

Aesthetic Considerations

Porcelain bushings have a more traditional appearance, while epoxy bushings are often gray or brown. The choice between the two may also involve aesthetic considerations, depending on the installation environment.

Cost

The cost of porcelain and epoxy bushings can vary depending on factors such as size, voltage rating, and manufacturing processes. Generally, epoxy bushings may be more cost-effective due to their lighter weight and reduced maintenance requirements.

Conclusion

In the world of electrical insulation, the choice between porcelain and epoxy bushings is not a one-size-fits-all decision. Both materials offer excellent electrical insulation properties, but they have distinct characteristics and are better suited to specific applications.

Porcelain bushings, with their long history of reliability, remain a viable choice for many indoor and outdoor installations. However, they may require more maintenance in polluted environments and can be heavier to handle.

Epoxy bushings, a more recent innovation, have gained popularity for their pollution resistance, lightweight construction, and reduced maintenance requirements. They are often the preferred choice in outdoor applications and challenging operating conditions.

Ultimately, the selection of bushing material should be based on a careful assessment of the specific requirements of the electrical system, taking into account factors such as voltage level, environmental conditions, and installation considerations. Engineers and professionals must weigh these factors to make informed decisions that ensure the safety and reliability of their electrical systems.