-

10KV Epoxy Resin Busbar Support Insulators High Voltage Insulator

A 10KV epoxy resin busbar support insulator is a specialized component used in electrical power distribution systems to support and insulate high-voltage busbars. Here’s a description of this type of high-voltage insulator:

1. Voltage Rating:

A 10KV epoxy resin busbar support insulator is designed to withstand a voltage level of 10,000 volts without electrical breakdown. It is engineered to provide reliable electrical insulation in high-voltage applications.

2. Material:

These insulators are typically made from epoxy resin, a material known for its excellent electrical insulation properties, mechanical strength, and resistance to environmental factors. The epoxy resin used is specially formulated to meet the high-voltage requirements.

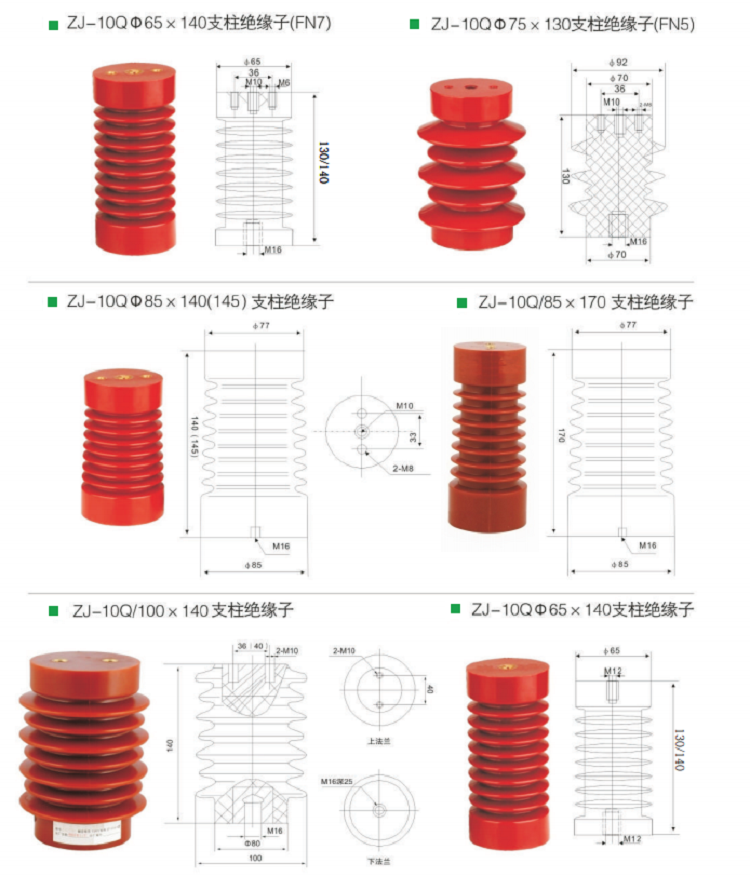

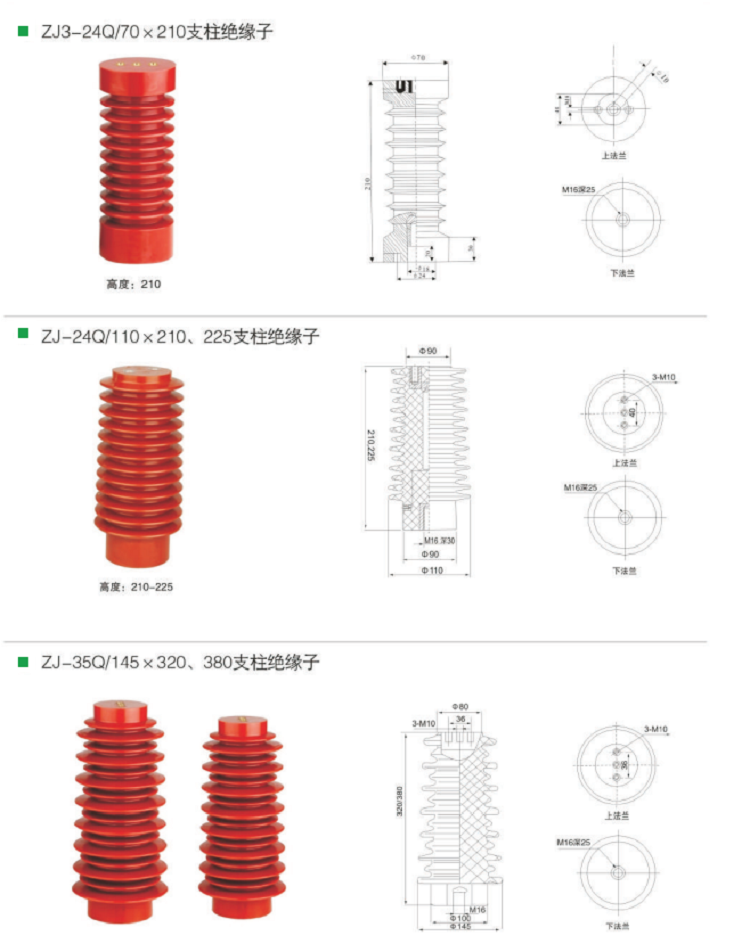

3. Design and Shape:

Busbar support insulators come in various shapes and designs, including cylindrical, conical, and post insulators. The specific design may vary depending on the manufacturer and the requirements of the installation. The insulator’s shape is critical for ensuring proper electrical and mechanical performance.

4. Creepage Distance:

Creepage distance is the shortest path along the surface of the insulator between two conductive parts. It’s essential that the creepage distance of a 10KV epoxy resin insulator is sufficient to prevent electrical arcing and maintain safe operation under high voltage.

5. Manufacturing Process:

The manufacturing process typically involves casting or molding the epoxy resin into the desired insulator shape, curing it to achieve the required properties, and subjecting it to quality control tests. The process ensures the insulator meets electrical and mechanical standards.

6. Application:

These insulators are used primarily to support and insulate busbars in electrical switchgear, substations, and other high-voltage equipment. They play a critical role in preventing electrical discharge and ensuring the safe and reliable operation of the equipment.

7. Safety:

When dealing with high-voltage equipment, safety is paramount. Proper installation procedures and safety precautions should be followed to prevent accidents and ensure the insulators perform their insulation and support functions effectively.

8. Customization:

Manufacturers may offer customization options to meet specific user requirements, including variations in size, shape, and voltage rating, to ensure compatibility with various electrical installations.

In summary, a 10KV epoxy resin busbar support insulator is a specialized component designed to provide electrical insulation and mechanical support in high-voltage environments. These insulators are crucial for maintaining the safety and reliability of electrical power distribution systems

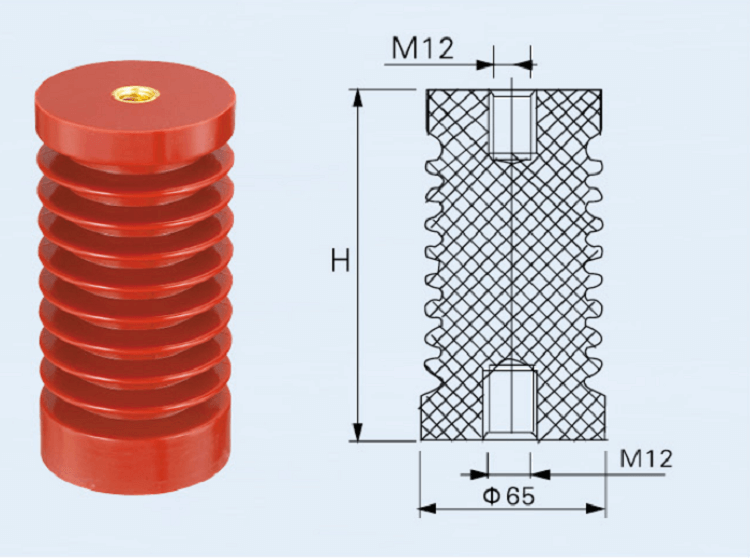

- Voltage:

10kv Height: 130/140mm Diameter: 65mm Screw: M12 Material: Epoxy resin MOQ: 50pcs Certificate: CE, RoHS, REACH

High voltage standoff insulator description

- Epoxy Vacuum Pouring Technology: Epoxy vacuum pouring technology involves casting epoxy resin in a mold under vacuum conditions. This process helps remove air bubbles and ensures a uniform and void-free distribution of the epoxy material. It’s a common method for manufacturing high-voltage insulators due to its ability to create reliable and consistent insulation properties. Epoxy vacuum pouring is often used for insulators that require complex shapes or high precision.

- APG (Automatic Pressure Gelation) Technology: APG technology is used for molding components such as bushings, contact boxes, insulating cylinders, and bell housings. In APG, epoxy resin is mixed with a hardening agent and injected into a mold, where it undergoes a chemical reaction under pressure and heat to solidify. This method is known for producing insulators with excellent mechanical strength and electrical insulation properties. It’s particularly well-suited for components that need to withstand high voltage.

- SMC (Sheet Molding Compound) and DMC (Dough Molding Compound) Unsaturated Alkyd Enlargement Mode Plastic: SMC and DMC are composite materials made of resins, fiberglass, and fillers. They are used for compacting molding, which involves compressing the material into the desired shape and then curing it. These materials are known for their high mechanical strength and are often used for insulators that require robust mechanical support.

- Voltage Range: The insulators you mentioned are designed to operate in a voltage range of 3.6 KV to 40.5 KV. This indicates their suitability for mid to large-voltage switchboards and other high-voltage applications within this voltage range.

- Applications: The insulators produced using these various technologies are applied in mid to large voltage switchboards. They play a critical role in electrical power distribution and are essential for maintaining electrical insulation and mechanical support in high-voltage environments.

Application

Applicable to all shopping malls, supermarkets, national grids, substations, power energy, urban power and other fields.

Mainly used in switch cabinets, power stations, outdoor high voltage, switchgear, etc.

Our service

| Delivery | By express/By sea/By air/By land transportation |

| Supply | 5000pcs/week |

| Sample | The seller provides 2 samples for free, and the buyer pays the freight |

| Packing | By carton |

More Related